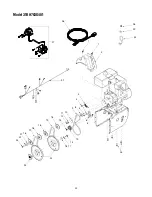

13

Augers

•

The augers are secured to the spiral shaft with two

shear bolts and hex lock nuts. If you hit a hard

foreign object or ice jam, the snow thrower is

designed so that the bolts may shear.

Refer to Figure 13.

•

If the augers will not turn, check to see if the bolts

have sheared. Replacement shear bolts and hex

lock nuts have been provided with the snow

thrower. When replacing bolts, spray an oil

lubricant into shaft before inserting new bolts.

IMPORTANT:

NEVER replace the auger shear bolts with

standard hex bolts. Any damage to the auger gearbox

or other components as a result of doing so will NOT be

covered by your snow thrower’s warranty.

Shave Plate and Skid Shoes

•

The shave plate and skid shoes on the bottom of

the snow thrower are subject to wear. They should

be checked periodically and replaced when

necessary.

•

To remove skid shoes, remove the four carriage

bolts, cupped washers and hex nuts which attach

them to the snow thrower. Reassemble new skid

shoes with the four carriage bolts, cupped washers

(cupped side goes against skid shoes) and hex

nuts. See Figure 14.

Figure 14

Belt Removal And Replacement

Auger Belts

NOTE: It is necessary to remove both belts in order to

change either one. If changing just one belt, be certain

to check the condition of the other belt.

•

Remove the plastic belt cover at the front of the

engine by removing the two self-tapping screws.

See Figure 15.

•

Drain the gasoline from the snow thrower, or place

a piece of plastic film under the gas cap.

•

Tip the snow thrower up and forward so that it rests

on its auger housing.

Figure 15

•

Remove the six self-tapping screws from the frame

cover underneath the snow thrower.

•

Roll the front and rear auger belts off the engine

pulley. See Figure 16.

•

Unhook the idler spring from the hex bolt on the

auger housing. See Figure 17.

•

Back out the stop bolt until the support bracket

rests on the auger pulley.

NOTE: Loosening the six nuts that connect the frame to

the auger housing may aid in belt removal.

Figure 16

•

Lift the auger belt from the auger pulley, and slip

belt between the support bracket and the auger

pulley. Repeat this step for the front auger belt.

•

Replace the auger drive belts by following

instructions in reverse order.

NOTE: If you placed plastic film under the gas cap, be

certain to remove it before operating the snow thrower.

Carriage

Skid Shoe

Hex Nuts

Shave Plate

Bolts

Skid Shoe

Self-Tapping

Screw

Belt Cover

Auger

Pulley

Drive

Pulley

Drive

Belt

Idler

Pulley

Idler

Pulley

Auger

Belts

Frame