5. Inspection and servicing of basic engine parts

126R1

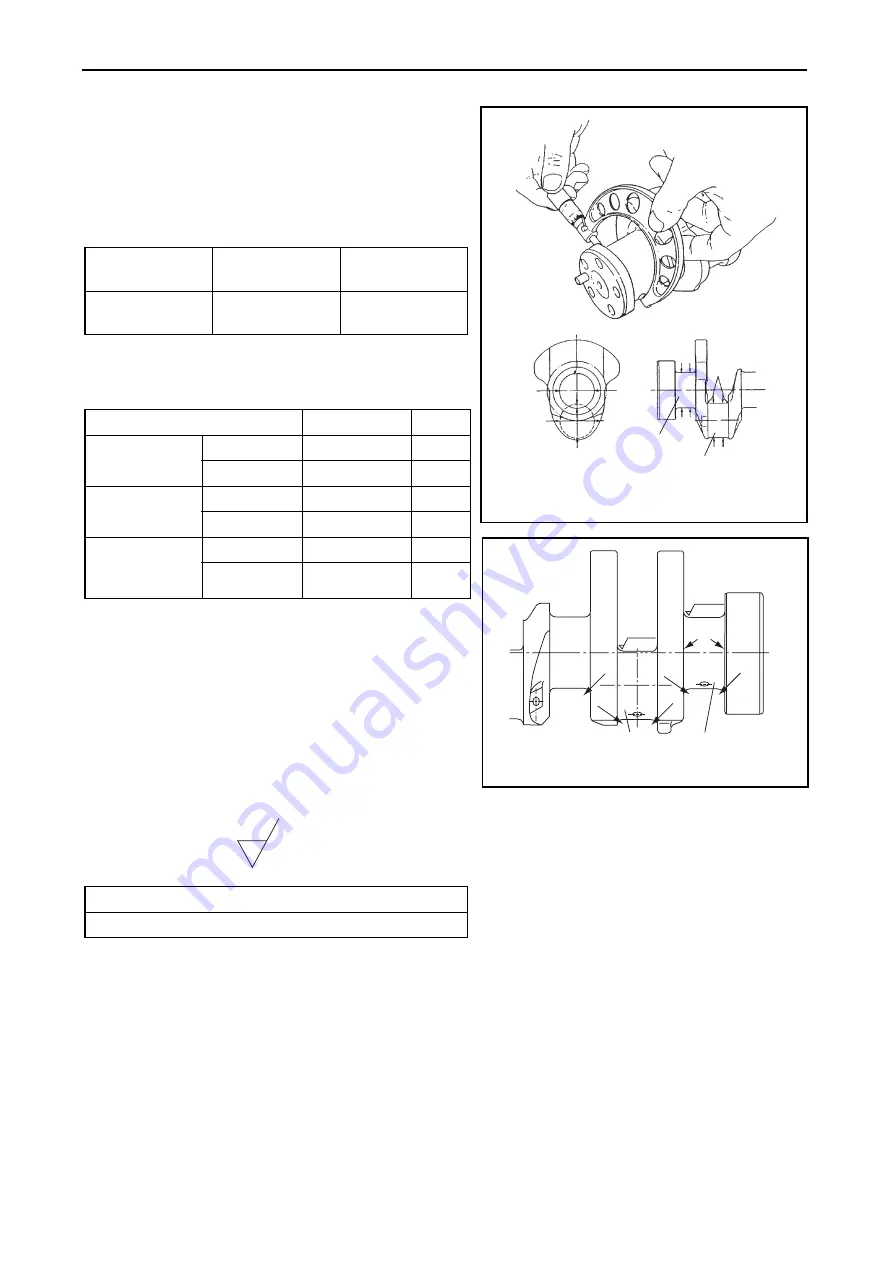

(3) Measuring the crank pin and journal

Measure the outside diameter, roundness and taper at

each crank pin and journal.

Correct by grinding if unevenly wear, roundness

exceeding the limit or insufficient outside diameter is

found. Replace if the defect is excessive.

To look for the oil clearance of crank pin, measure the

inside diameter of crank pin metal. (Refer to 5.4.2(2). )

• Dimension R and finishing precision of crankshaft

journal and pin

As for grinding processing of journal and pin, machine

it by using the grinding wheel of the dimension R of

below table.

Surface finishing precision standard on journal and

pin:

Ry = 0.8S super polishing

Surface finishing precision standard on the thrust side

of crankshaft arm :

NOTICE:

1) lf the oil clearance is excessive though the thickness of the journal and crankpin metals are normal

or if partial uneven wear is observed, re-grind the crankshaft and use an undersize metals.

2) lf rust or surface roughening exists on the rear side of the metals, coat it with blue or minimum.

Then assemble the crankpin metal to the connecting rod, and tighten the rod bolt to the specified

torque to check the metal for contact. lf the contact surface occupies 75% or more, the metal is

normal. lf the contact surface is insufficient, the metal interference is insufficient. Replace the metal

with a new one.

mm

Item

Standard

(Diameter)

Limit

(Diameter)

Roundness

Taper

0.01 or less

0.02

mm

Standard

Limit

Crank pin

3YM30

Outside dia.

41.952-41.962 41.902

Oil clearance

0.020-0.058

0.120

Crank pin

3YM20/2YM15

Outside dia.

37.952-37.962 37.902

Oil clearance

0.020-0.058

0.120

Crank journal

(Selective pair)

All models

Outside dia.

46.952-46.962 46.902

Oil clearance

0.020-0.050

0.120

Finishing precision standard of dimension R (mm)

3.5+0.3/0

Crankshaft

journal

Crank pin

Measuring position of the crank pin

and crank journal

)

(

Super

polishing

Ry=0.8S

Super

polishing

Thrust

face

Crank Pin

(Crankshaft R machining)

Crank Journal

Ry=0.8S

R

R

R

R

R

1.6

Содержание 3YM30

Страница 1: ...M9961 03E101 3YM30 3YM20 2YM15...

Страница 22: ...1 General 1 4 Engine outline 1 3YM30 with KM2P 1 marine gear 6R1...

Страница 23: ...1 General 2 3YM30C with SD20 sail drive 7R1...

Страница 24: ...1 General 3 3YM20 with KM2P 1 marine gear 8...

Страница 26: ...1 General 5 2YM15 with KM2P 1 marine gear 9 2R1...

Страница 27: ...1 General 6 2YM15C with SD20 sail drive 185 9 3R1...

Страница 30: ...1 General 3 2YM15 with KM2P 1 marine gear 11 2R1...

Страница 31: ...1 General 11 3R1 4 2YM15C with sale drive SD20...

Страница 46: ...2 Inspection and adjustment 26 Cylinder head Bracket Fuel filter Fuel pipe Fuel injection pump Clamp Fuel pipe...

Страница 160: ...6 Fuel injection equipment 139 6 1 3 Fuel injection pump structure Section of a fuel injection pump governor for 3YM30...