O P E R A T I O N & M A I N T E N A N C E M A N U A L

29

clean diesel when grinding. Grinding in pairs shall not impact on the needle valve or its

stand, and clean after grinding without any metal dirt reserved.

4

、

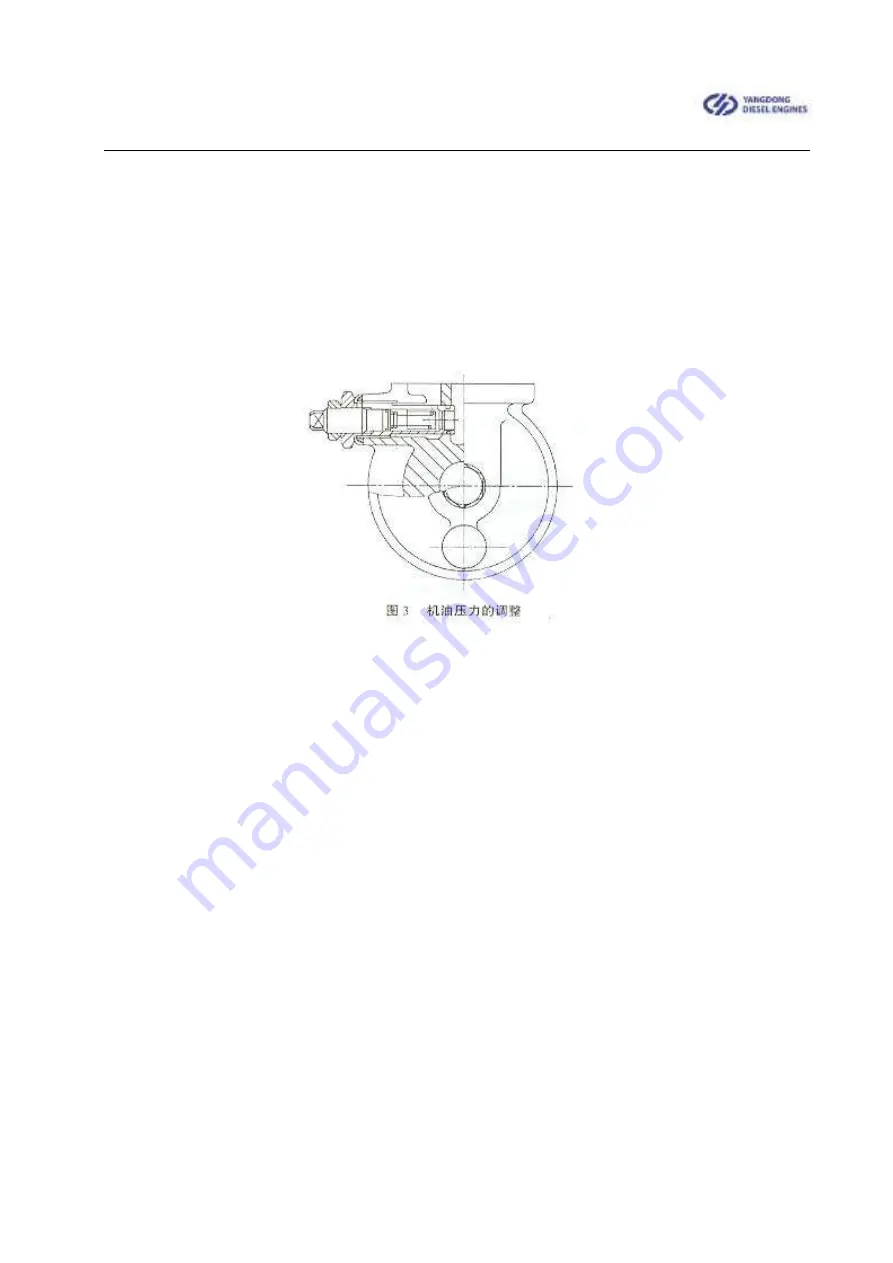

Adjustment of lube oil pressure

Adjustment of oil pressure is shown in Figure 3. Loosen and fasten the nuts; adjust the

nuts with spanner to make the oil pressure within 200-400kPa (it is allowed to be

higher when the machine is cold). Screw up the nuts after adjustment.

Figure 3:

adjustment of lube oil pressure

5

、

Adjustment of injection pump

The oil injection pump has been adjusted and checked before delivery. If

re-adjustment is required, it shall be carried out on special oil injection pump test bend

fro standard oil injector and standard length high pressure oil pipe according to relevant

instructions on oil injection pump.

6

、

Adjustment of decompression arm lash

Turn the Crank to the first cylinder piston stop position, when the “0” scale on the crank

belt wheel aims exactly with the indicator in the timing gear cover. Inset the thick and thin

dividers respectively into the air inlet and exhaust valves of the first cylinder and the

rocker, check and adjust the clearance between the air valves and keep the cool

clearance between within regulated value. After that, according to the cylinder working

order to half rotate the vcrand and adjust the clearance between the air valves.