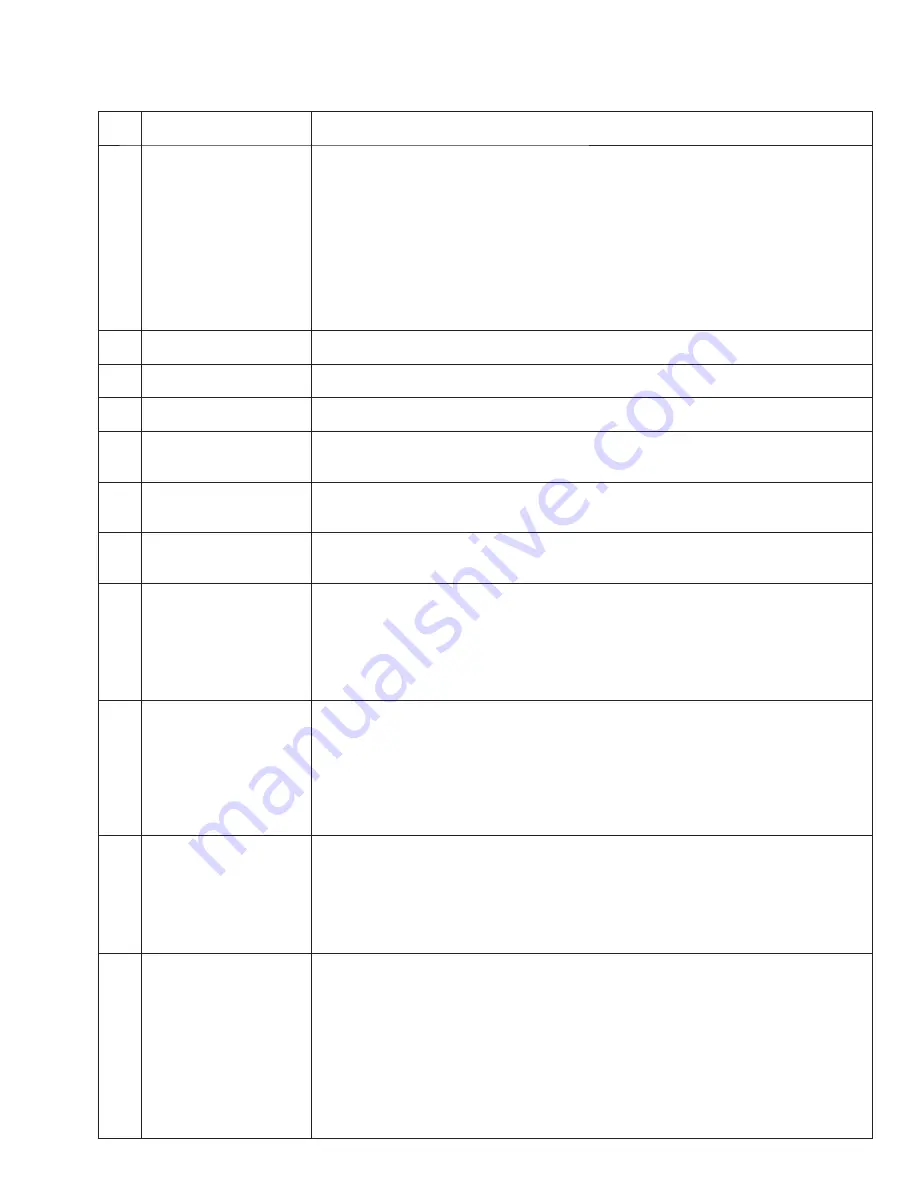

Test

LCD display

Test description, judging conditions, etc.

No.

011

011: SW, LED Chk

Every time each switch is pressed, confirm the following test items.

•

The corresponding pitch sound is output normally.

•

“On” is displayed on the LCD.

•

No key stick is existed.

•

Confirm the LEDs light one by one.

When the test is finished, “End” is displayed on the LCD.

(OK: “[

***

] 0n” / NG: “NG:O=xxxx([

***

]) X=xxxx([

***

])”,

If multiple switches are pressed together: “Over Two Sw”)

(

***

= Panel switch name)

If the [EXIT] switch is pressed twice, this inspection is cancelled

and return to the test item selection mode.

012

012: All LED On

Checks all LEDs on the panel.

All the LEDs light together. Confirm all the panel LEDs light normally.

013

Red LED On

Checks all the red LEDs on the panel.

All the red LEDs light together. Confirm all the lighting LEDs are red.

014

014: Green LED On

Checks all the green LEDs on the panel.

All the green LEDs light together. Confirm all the lighting LEDs are green.

015

015: All LCD On Chk

Checks all dots of LCD.

All dots of LCD are turned on.

Confirm the whole LCD screen becomes white.

016

016: All LCD Off Chk

Checks all dots of LCD.

All dots of LCD are turned off.

Confirm the whole LCD screen becomes blue.

017

017: LCD Contrast Chk

Checks LCD Contrast.

Adjust the contrast by pressing [DEC/NO] (to lighten) and [INC/YES] (to darken) buttons.

Confirm the contrast changes in 8 stages.

018

018: Encoder Chk

Checks the encoders.

Turn the encoder clockwise, with increasing count number up to “+8”.

Then turn it counterclockwise, with decreasing count number down to “-8”.

Confirm the encoder moves smoothly.

Thereby “OK” is displayed for the encoder.

After executing the test, confirm that “OK” is displayed on the LCD.

(OK: “OK”)

019

019: Pitch Bend Chk

Checks the pitch bend wheel.

Rotate the pitch bend wheel up to maximum, and the C3 note is output.

Then, rotate the wheel down to minimum, and the G3 note is output.

Finally, rotate the wheel to the center position, and the C4 note is output.

Confirm the wheel moves smoothly.

(“PitchBendUp:yy”, “PitchBendDown:yy”, “PitchBendCenter:yy”) / yy = Current value

After executing the test, confirm that “OK” is displayed on the LCD.

(OK: “OK”)

020

019: Pitch Bend Chk

Checks the modulation wheel.

Rotate the modulation wheel up to maximum, and the C3 note is output.

Then, rotate the wheel down to minimum, and the G3 note is output.

Confirm the wheel moves smoothly.

After executing the test, confirm that “OK” is displayed on the LCD.

(“ModWheelUp:yy”, “ModWheelDown:yy”) / yy = Current value

(OK: “OK”)

021

021: Volume Chk

Checks the volume knobs

Turn a volume counterclockwise, with decreasing count number down to “0”.

Then turn it clockwise, with increasing count number up to “127”.

Then turn it counterclockwise, with decreasing count number down to “64”.

Thereby “OK” is displayed for the volume.

Execute the above procedures for all the volumes one by one.

The order of inspection is not constrained.

Confirm each volume moves smoothly.

After executing the test, confirm that “OK” is displayed on the LCD.

(Indication for each volume: “<xx>yy”) / xx = Target value, yy = Current value

(OK: “OK”)

33

MX61/MX49

Содержание MX49

Страница 15: ... R8A02042BG YC479A00 SWX08 DM IC101 15 MX61 MX49 ...

Страница 16: ...16 MX61 MX49 ...

Страница 21: ...B B B B DM Circuit Board 2NA ZA67560 1 Pattern side パターン側 21 MX61 MX49 ...

Страница 26: ...to DM CN402 to 61H CN3 F F F F 49L Circuit Board MX49 only Component side 部品側 2NA ZA13490 26 MX61 MX49 ...

Страница 27: ...G G G G 49L Circuit Board MX49 only 2NA ZA13490 Pattern side パターン側 27 MX61 MX49 ...