5

4. How to Operate the Machine

CAUTION

- The supply air pressure should be 0.7 MPa or less. If the primary pressure

is more than 0.7 MPa, adjust the pressure to 0.7 MPa or less.

- After the end of daily work or when the machine is not operated for a long

time, be sure to shut off the supply air and bleed the internal pressure of the

pump, hose, and gun.

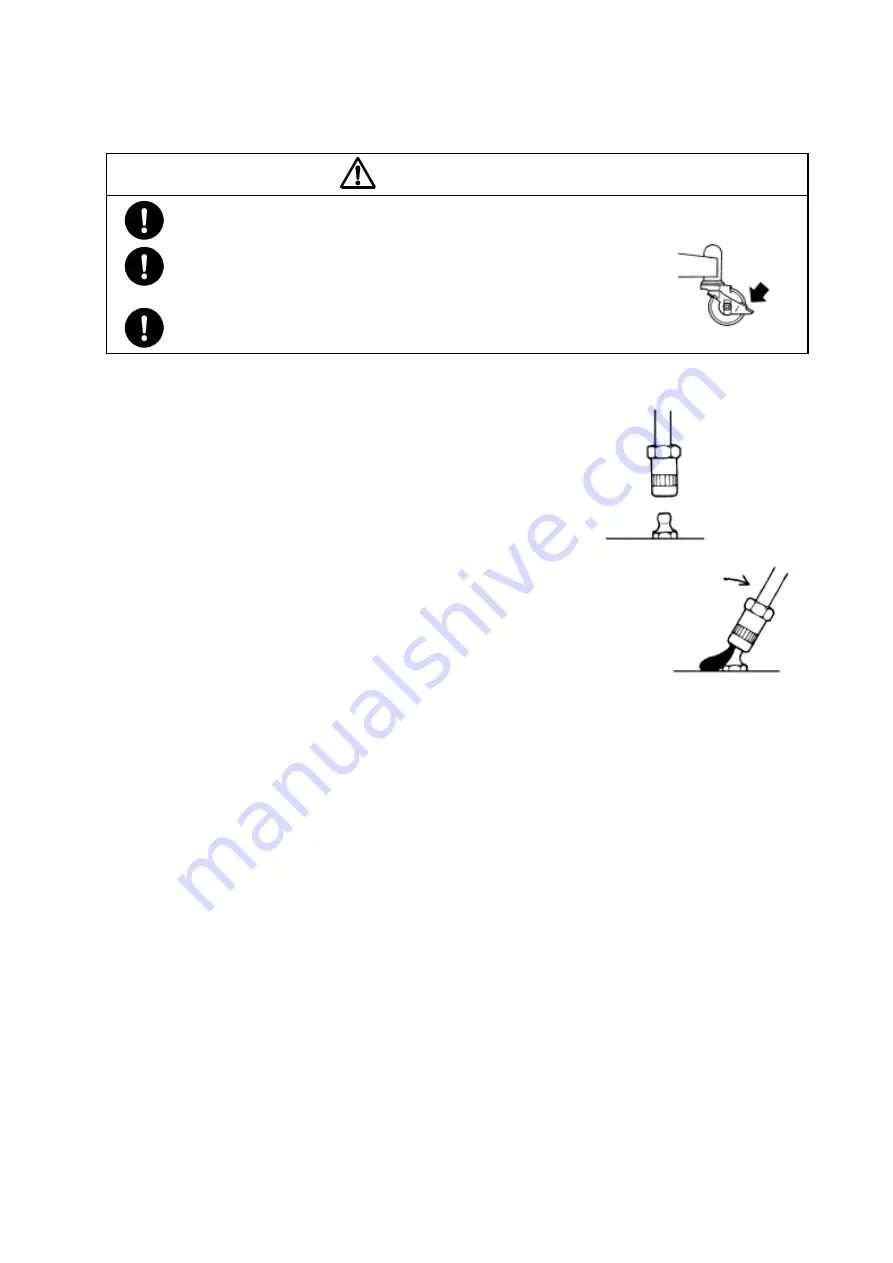

- During machine operation or after completion of movement, be sure to lock

the caster brake for locking. (Fig. 6)

1) Wipe the grease nipple to be used for greasing cleanly. After that, push

the chuck at the end of the grease gun against the nipple to perform

chucking as vertically as possible. (Fig. 7)

2) Pull the gun lever to supply grease. When grease is normally injected, old

grease will be squeezed out from the groove or clearance near the nipple.

3) After completion of grease supply, release the gun lever. The pump will be

automatically stopped.

4) Remove the chuck at the end of the grease gun.

Since pressure is applied to the chuck, the head of the nipple may be

broken if it is suddenly pulled. Incline the chuck to bleed the internal

pressure, and the chuck can be easily removed. (Fig. 8)

5) After completion of greasing work, be sure to shut off the supply air of the

pump and bleed the internal air of the hose.

6) If the pump is suddenly started, it may be due to non- existence of grease

in the pail can or an air pocket produced. Stop the greasing work and

make a check.

7) Exchange the pail when the grease stopped coming out.

Fig. 7

Fig. 8

Fig. 6