-

19

-

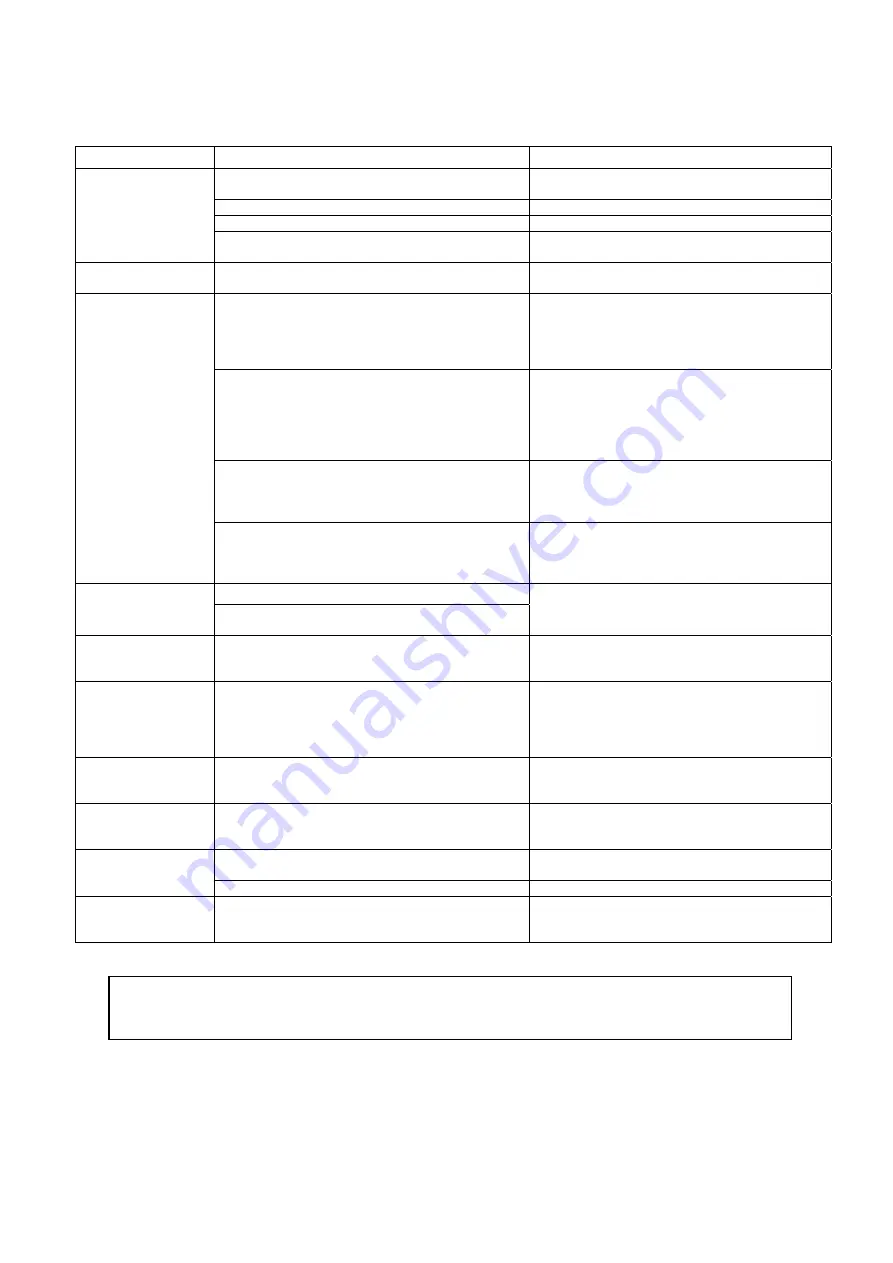

TROUBLESHOOTING

State

Cause

Action to be taken

Pump does not run

Air is not supplied.

Start the compressor, and open the air valve and

air regulator.

The supply pressure is low.

Set the air pressure to 30 psi or more.

The discharge flow valve is not open.

Open the ink delivery valve.

Icing inside exhaust port.

Install air line coalescing filter to remove

moisture.

Pump does not prime

ink during stat up.

The supply air pressure is too high.

Until pump discharge ink from bleeder valve, run

pump 8-10 cycle per minute.

Pump does not

deliver ink

If the plunger operates faster during the moving-up

process, the seat of the piston valve malfunctions

(the seat section is worn out or a foreign substance

is mixed into the valve), or the packing or similar

part is damaged.

Replace the malfunctioning part with a new one,

or remove the foreign substance.

If the plunger operates faster during the

moving-down process, the seat of the foot valve

malfunctions (the seat section is worn out or a

foreign substance is mixed into the valve), the

packing or similar part is damaged, or the shovel

rod is bent.

Replace the malfunctioning part with a new one,

or remove the foreign substance.

If the plunger operates faster during the

moving-down process, the pump operates at a

speed too high for the lower pump to suck ink (the

lower pump is evacuated).

Decrease the air pressure so that this

phenomenon cannot occur (under this condition,

the air pressure you set at this point is the upper

limit the pump can operate at normally).

The screw or other part that fix the air motor and the

plunger of the lower pump is loosened, and then

removed completely (a part located inside the lower

pump may be damaged).

After checking the inside of the lower pump,

replace the damaged part with a new one, and

tighten the removed screw(s) securely.

The pump does not

stop.

Ink leakage from the ink delivery pipe connection.

Tighten the screw fixed at the malfunctioning

section further or replace the damaged part with a

new one.

Ink leakage from the parts-connecting section of the

suction pump assembly.

Air leakage form the

air motor

The screws that connect parts is loosened, or the

O-ring, packing or similar part is damaged.

Tighten the screw fixed at the malfunctioning

section further, or replace the damaged part with

a new one.

Air leakage from the

silencer during stop

A foreign substance is caught between the block

inside the switching valve (804355 or 804358) and

the sliding section of the switching valve seat

(705688), the seat is worn out, or the gasket

(772331) is damaged.

Replace the damaged part with a new one, or

remove the foreign substance.

Ink leakage from the

suction pump

The screws that connect parts is loosened, or the

O-ring, back-up ring, packing or other similar part is

damaged.

Tighten the screw fixed at the malfunctioning

section further, or replace the damaged part with

a new one.

Air entrained in ink

The screws that connect parts of the lower pump is

loosened, or the O-ring, back-up ring, or gasket is

damaged.

Tighten the screw fixed at the malfunctioning

section further, or replace the damaged part with

a new one.

The oil container

swells (is dissolved)

Without Overflow catch bottle.

Put in Overflow catch bottle, when you operate

pump.

Solvent attacks acrylic resin.

Use spindle oil (ISO viscosity grade 10).

The amount of liquid

increases rapidly in

the oil container.

The gland seal is worn out or damaged.

Replace the gland seal with a new one.

----- RETAIN THIS INFORMATION FOR FUTURE REFERENCE-----

For accurate and speedy shipment of parts, be sure to order the right parts for your model from your distributor.

Indicate the part numbers, descriptions, and quantities.