2

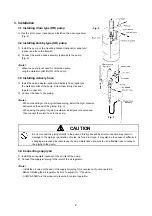

3. Installation

3.1 Installing drum type (DR) pump

1) Use the drum cover (optional) and install on the open type drum.

(Fig. 2)

3.2 Installing stubby type (SH) pump

1) Install the pump on the mounting bracket (optional) or panel unit

(option) and fix on the flat wall.

2) Connect the suction hose assembly (optional) to the pump.

(Fig. 3)

<Note>

When the pump is not used for circulation pump,

plug the material outlet (Rc3/4) of the pump.

3.3 Installing delivery hose

1) Install the union adapter (option) and delivery hose (option) at

the material outlet of the pump. Screw them firmly. Use seal

tape for connection.

2) Connect the hose to the piping.

<Note>

-

When connecting to the long-distance piping, install the high- pressure

ball valve at the end of the piping. (Fig. 3)

- When using the pump for paint circulation, install pressure valve and

then connect the return hose to the pump.

CAUTION

- Do not connect the piping directly to the pump. Vibration caused by direct connection may result in

damage to the piping or generation of noise. As for a drum type, it may also be the cause of difficulty in

changing a drum and inconvenience of pump maintenance. Be sure to use a flexible hose to connect

the piping to the pump.

3.4 Connecting supply air

1) Install the air regulator (option) at the air inlet of the pump.

2) Connect the supply air piping to the inlet of the air regulator.

<Note>

-

Install the air valve at the end of the supply air piping for convenience of pump operation.

Before installing the air regulator, be sure to adjust it to “0” position.

- 0.3MPa~0.5MPa is the proper air pressure for normal operation.

Fig. 2

Fig. 3

Содержание 110 Series

Страница 17: ...MEMO ...