4

Installation

03.2018

31

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

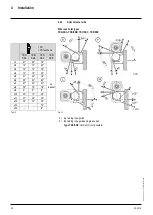

4.3.6

Articulated trolley (DKE-S4 / DKE-S6)

with YKA/SKA, YKB/SKB, YKC/SKC wire rope hoists

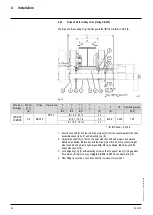

Fig. 20

Wire rope

hoist type Ø D

Trolley

B

f/2

c

x y Z max

Tightening torque

Nut (3) Nut (5)

[in]

[in]

[lb

f

ft]

YKA/SKA,

YKB/SKB

3.9 DKE-S4 3.5 - 11.8 0.059 B+3.1 2.6 5.8 1.1

159

63

YKC/SKC 5.5 DKE-S6 4.7 - 11.8 0.059 B+3.3 3 6.3 1.6

159

63

Tab. 13

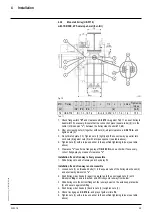

1.

Check flange width

“B”

and clearance

“c”

against Tab. 13 and set trolley to beam

width if necessary.

2.

Ensure that the connection piece (square tube) (6) is in the center (of dimension

“c”

)

between the trolley side cheeks.

3.

After unscrewing nuts (3) together w

ith nuts (2), adjust clearance “

c”

and tighten

nuts (3).

4.

Tighten nuts (3) with a torque spanner to the specified tightening torque (see table

above).

5.

Clearance

“c”

results in a flange play of

f/2 +0.039 in.

on each side. If necessary,

correct flange play by means of clearance

“c”

.

Installation if end of runway is freely accessible

1.

Slide trolley onto end of runway.