4

Installation

30

03.2018

ba

-o

.2

.6

.0

-us

-1.

1-

y

|

A

11

86

75

01

R

ev

A

A

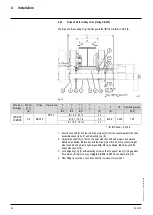

Centering connection piece

1.

Loosen nuts (5) and shift connection piece (6) on connecting bolt (7) so that

dimensions

“z1”

and

“z2”

between trolley side cheeks (4) and connection piece (6)

are equal on both sides.

2.

Tighten nuts (5) with a torque spanner to the specified tightening torque (see table

above).

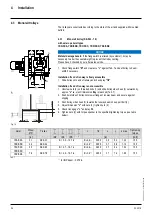

Connecting bolt and drive shaft

3.

Use connecting bolt and drive shaft suitable for beam range

“B”

(for dimensions, see

Fig. 19).

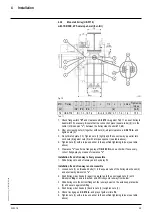

Drive shaft for trolley drive (trolley UE-S776)

Fig. 19

B

L

L1

L2

f/2

[in]

[in]

[in]

[in]

[in]

7.3 - 8.7

20.1

3.3

5.1 - 3.7

0.059

8.7 - 14.2

24.4

3.3

6.8 - 1.3

14.2 - 17.7

29.1

5.3

3.9 - 0.35

17.8 - 19.7

29.1

3.3

2.3 - 0.35

Tab. 12

The drive shaft is suitable for girder flange widths

“B”

from

7.3 in.

to

19.7 in

. (see Tab.

12 for length

“L”

).

1.

Insert drive shaft (1) into the two drive pinions (6) from the counterweight side, then

assemble spacer tube (3) and adjusting ring (4).

2.

Adjust drive shaft (1) to dimension

“

L1

”

,

dimension

“

L2

”

must lie between the values

given in the table.

3.

Lock adjusting ring (4) with adjusting screw.

4.

After fitting travel drive, check drive shaft (1) for ease of movement. The axial play

must be approx.

2

–

4 mm (0.08

–

1.57 in.)