28

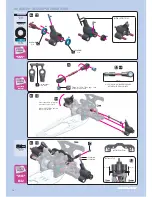

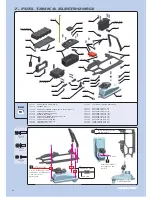

ENGINE & CLUTCH

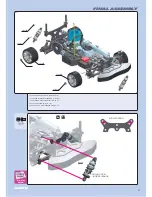

Pull the clutchbell away from the clutch

shoe and measure distance B as

indicated.

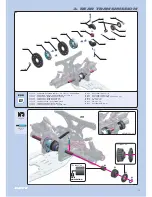

338584

S 5x7x0.2

338585

S 5x7x0.3

338586

S 5x7x0.5

930150

BA 5x10

940508

BB 5x8x2.5

359050

BB 5x10x4

908316

SCH M3x16

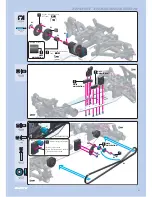

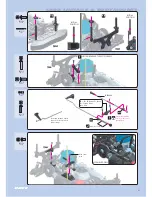

10~11mm

DETAIL

These shims are used to adjust

clutchbell endplay.

A

Measure endplay with this bearing installed

DETAIL

NOTE ORIENTATION

9.2 +0.1mm

ø10mm

ø9.8mm

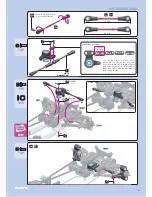

Pull

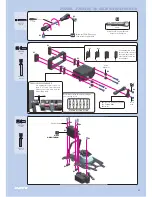

Install the clutchbell, outer ball-bearing

(small), and thrustbearing assembly on

the engine crankshaft. DO NOT install

the inner ball-bearing or internal shims.

Push the clutchbell onto the clutch shoe

and measure distance A as indicated.

Push

B

The clutch gap is A - B;

the correct gap is 0.6-0.7mm

If the clutch gap is greater than this,

you can easily calculate the thickness

of shims required to set correct gap:

Thickness of shims required

in mm = A-B-0.7

Apply shims on crankshaft to set endplay

to 0.05-0.15mm

1)

ADJUSTING THE CLUTCH GAP

ENDPLAY SHIMS

CLUTCH GAP SHIMS

These shim are used

to adjust clutch gap.

To meassure the clutch gap

you can also use HUDY

Flywheel Tool #182010

➊

➋

➌

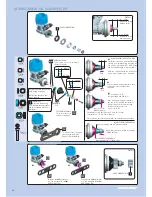

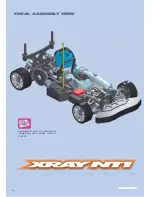

To tighten the

21T

pinion gear

use the optional #182002

HUDY Pinion Tool.

To tighten the

16T

pinion gear

use the optional #182001

HUDY Pinion Tool.

NOTE ORIENTATION

➊

➋

BEARING

OIL

Adjust with spring

preload collar

Adjust with shims

behind fl ywheel

DO NOT INSTALL this bearing

when setting clutch gap

INSTALL this bearing when

setting endplay

2)

ADJUSTING THE ENDPLAY

ø5.2mm

ø5.0mm

IMPORTANT

Degrease this bearing

with standard bearing cleaner,

and then lubricate with light

bearing oil.

Insert CLUTCH

GAP SHIMS here

For example, using the values A=5.5mm, B=4.5mm

Shim thickness = 5.5-4.5-0.7=0.3mm

Place shims on the small collar, outside the thrustbearing assembly.

Insert ENDPLAY SHIMS here

(Approximately 0.7~1.0mm shim)