https://www.XPOtool.com

Item 64076

Page 15

The Tool Experts

06 2023

-1

Motor overheats

Fuel is too thin

Set the carburettor.

Cylinder is polluted

Clean the cylinder.

Motor is very noisy or

stutters

False petrol oil mixing ratio

Drain fuel and replace.

Combustion chamber is polluted

Clean combustion chamber.

Moving parts are worn

Check and replace worn parts.

Motor shuts down while operating

Problem

Possible cause

Solution

Motor suddenly stops operat-

ing

Piston is blocked / torn

Repair or replace the piston.

Short circuit due to polluted spark

plug

Clean the spark plug.

Magneto is defect

Have the magneto be repaired or re-

placed.

The motor slowly turns off

Not enough fuel

Refuel.

Carburettor is polluted

Clean the carburettor.

Fuel is watery

Drain and replace the fuel.

Other problems

Problem

Possible cause

Solution

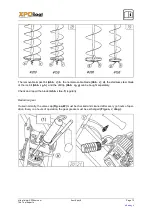

Motor operates, but au-

ger does not rotate

Coupling is damaged

Replace the coupling.

Auger does not properly fit the gearbox Replace with a fitting auger.

Gearbox emits unusual

noises

Gearbox is worn

Replace the worn parts.

Insufficient lubrication

Clean and grease the device.

Pollution inside the gearbox

Clean and grease the gearbox.

mportant!

Maintenance work not listed in this manual should only be carried out by qualified personnel.

Only original parts of the same quality should be used for repairs. No responsibility is assumed for

damage caused by improper maintenance or use.

Important notice:

The reprint or reproduction, even of excerpts, and any commercial use, even in part, of this instruction

manual require the written permission of WilTec Wildanger Technik GmbH.

I