https://www.XPOtool.com

Item 61909

Page 8

The Tool Experts

05 2022-1

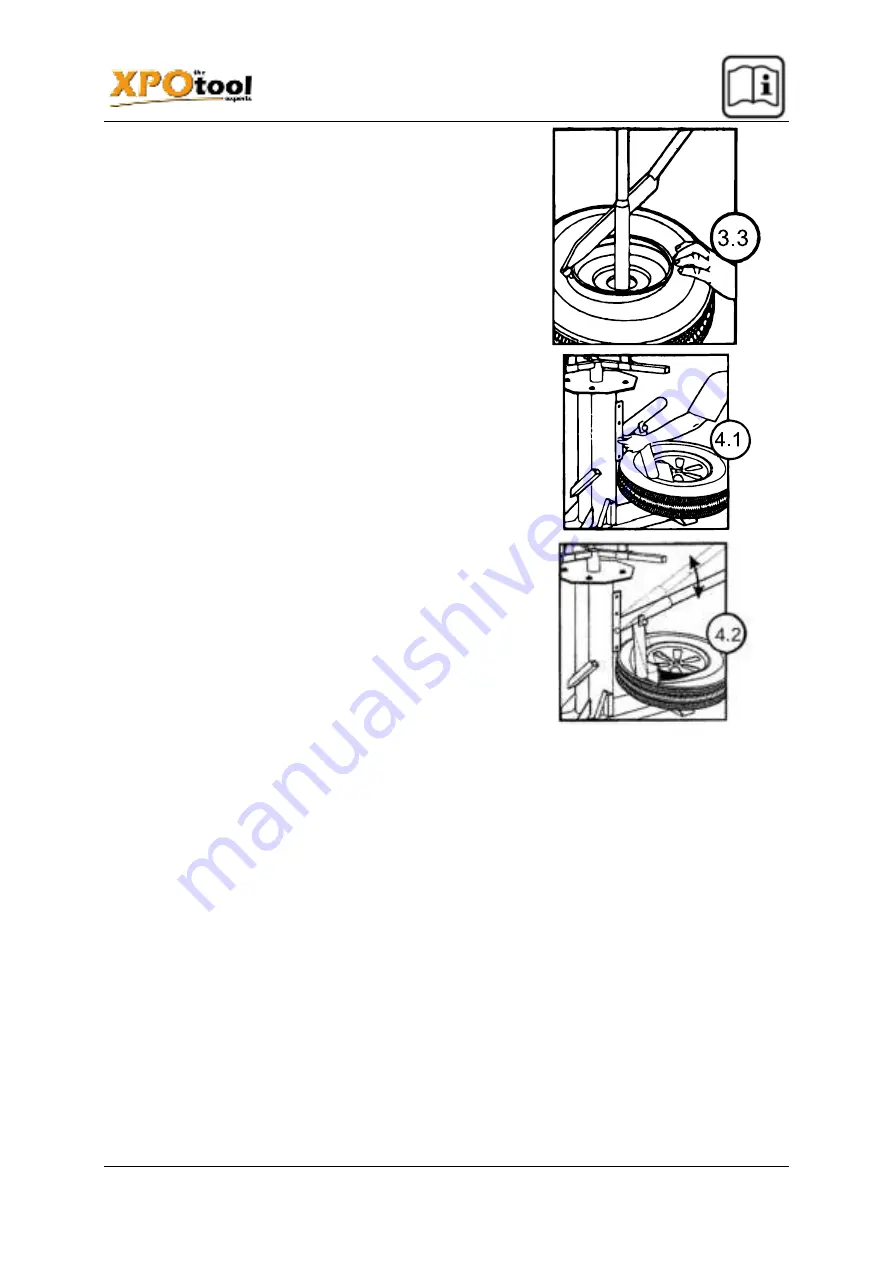

The tyre is mounted over the flat end of the tyre tool. Place the

ball head piece under pressure on the lower side of the tire (al-

ways facing the driver) between the rim and the bead. With the

flat side against the centre post, turn the tool full circle for cabin

lower and upper edges.

Bleed the tire and place the wheel on the fixing rod at the main

stand base. Position the bead protector in the bead area and

adjust the pivot bar on the main stand leg to the correct height.

Insert the demountable bar into the shoe and pull it down to

break the bead. If necessary, turn the tire 90° and repeat the

procedure. To break the bead on the other side, turn the wheel

over and repeat this step.

Caution!

It is important that a high-quality tyre lubricant is used during assembly and disassembly. Make

sure the bead is centred on the rim during the process. In the unlikely event that you will have trouble

turning the handle, use a tyre lever. Use a tyre iron to loosen the tire around the point of greatest re-

sistance.

Important:

Always lubricate the tyre!