Overview and Setup

3

INSTRUMENT LED INDICATOR

The LED indicates a variety of instrument operation conditions, such as calibration mode, and operation. Below is a

complete list of all conditions reported by the LED.

Operation Mode (Green Light)

•

Solid Green Light

—self test passed and instrument is ready for use with defined strip.

•

Slow Flashing Green Light—

strip reading in progress (strip being read)

.

•

Fast Flashing Green Light

—strip reading attempted but the wrong strip was inserted, or strip skewed during reading.

Calibration Mode (Yellow Light)

•

Solid Yellow Light

—instrument calibration was entered, ready to start calibration with next button press.

•

Slow Flashing Yellow Light

—instrument calibration in progress (strip being read).

•

Solid Green Light after Yellow Light

—instrument calibration was successful and instrument is ready for use.

•

Fast Flashing Yellow Light

—instrument calibration failed, re-read calibration strip. If error persists, clean instrument

and calibration strip (see Section Three). If error still persists, contact your Service Representative.

Error/Reset Mode (Red Light)

•

Solid Red Light

—and error was detected, the self test failed. Verify correct power supply is used. Turn power off,

reapply power and see if condition is corrected; if not, contact Service Representative.

•

Solid Green or Yellow changing to Red

—an instrument reset is in progress. To initiate a reset, press and hold the

button, the LED changes from Green or Yellow to Red. While the LED is Red, press button again (within 10

seconds). The LED changes to Green and the reset is performed, reinstating the factory defaults. If the second button

press is not performed when the LED is Red, the instrument will time-out, causing the LED to change to Green and

the reset to be aborted.

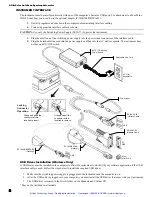

CHANGING THE POSITION OF THE BACKING BLOCK

NOTE: Instruments that utilize a “raised white backing block” cannot be repositioned.

The backing surface used when measuring paper strips can be alternated between ANSI Black and White Diffusing Opal.

The Backing Block is located on the bottom of the Base Assembly. Simply slide the block to the “right” for Black or to

the “left” for White (see below). The factory setting for reflection instruments is Black backing

. For transmission

instruments (DTP41/T), the optics block must remain in the “T/W” position (left) to measure film strips.

The block

can be slid to the “BL” position (right) for measuring paper strips with a black backing if desired.

Reflection Instrument

Slide block to the

left

for White

Diffusing Opal backing

“T/W” is visible with

White Opal

“BL” is visible with Black

Slide block to the

right

for

ANSI Black backing

Transmission Instrument

The optics block must be slid to the “T/W”

position (transmission) when measuring film

strips. A small screwdriver can be used to slide

the optics block from one position to the other.

Reflection Only

Slot for sliding block to the right

(ANSI Black backing)

Slot for sliding block to the

left

(default position)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Содержание AutoScan DTP41 Series

Страница 3: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Страница 7: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...

Страница 16: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com ...