14

Device elements

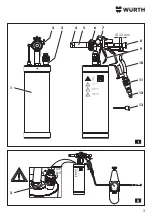

Overview [Fig. I]

1

Detachable tank

2

Air regulator

3

Air vent regulator and 8 bar safety valve

4

Nozzle cap

5

Nozzle holder

6

Union nut

7

Hanging eye

8

Nozzle regulator

9

Trigger lever

10

Handle

11

Air

supply

regulator

12

Compressed air supply R ¼“ internal thread

13

Hollow space probe*

*

Accessory (not supplied)

Intended Use

The device is intended for use in spraying bitumen,

rubber, plastic, synthetic resin and wax-based liquid

underseal/stone chip protection and hollow space

sealing products from special containers. The device

is intended for use with genuine Würth system acces

-

sories. Any other use is considered an improper use.

The user is solely responsible for damage

resulting from improper use.

Technical Data

Art.

0891 110 640

Air consumption

200 - 300 l/min

Working pressure

3 - 4 bar

Max. pressure:

8 bar

Recommended hose length 10 m

Min. inside diameter of the

hose

6 mm

Air connection

R 1/4" inside

A pressure reducer, a filter and a shut-off valve for

shutting off the air supply are required in the com

-

pressed air system.

Noise and Vibration Information

The equivalent continuous sound pressure level,

calculated on the A scale, is measured at a horizon

-

tal distance of 50 cm. For bituminous products, this

level is <80 dB(A).

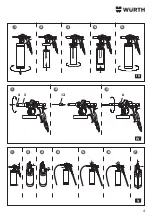

Operation (Fig. III)

Attention!

Dirty pipes could damage the device.

¾

Never tip the device through more than 45°.

¾

Do not close the device during use.

¾

After use, hand the device by the hanging

eye

[7]

.

■

Connect the nailer to the compressed air supply.

Observe the technical data.

WARNING!

Danger due to pressure release

Â

The detachable tank

[1]

is under

pressure.

¾

Before the detachable tank

[1]

is

unscrewed, the

safety valve

[3]

must be turned clockwise to

release the contained pressure.

■

Unscrew the detachable tank in an anticlockwise

direction (Fig. 1/III).

Using a 1 litre bottle

■

Remove the safety cap from the bottle

■

Punch a hole in the safety aluminium seal of the

bottle using the vertical tube.

■

Position the bottle and tighten in a clockwise

direction (Fig. 2/III and 3/III).

Содержание 0891 110 640

Страница 3: ...10 12 mm AIR EXIT 3 II I 8 7 3 3 1 2 10 11 12 9 4 5 6 13...

Страница 4: ...4 5 5 6 7 4 4 3 3 3 2 2 2 1 1 1 III IV V 4 5 6 13...

Страница 82: ...82 GR W rth 3 3 1...

Страница 83: ...83 18 16 8 bar...

Страница 85: ...85 9 8 1 V 2 2 V 3 3 V 11 9 3 4 V 2 9 8 360 9 5 V 2 6 V 8 2 7 V 8 4 5 III 10 30 9 3 3 IV 4 5 13 5 6 V 2...

Страница 86: ...86 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Страница 87: ...87 9 11 11 2 45 3...

Страница 138: ...138 BG W rth 3 3 1...

Страница 139: ...139 18 16 8 bar...

Страница 141: ...141 9 8 1 V 2 2 V 3 3 V 11 9 3 4 V 2 9 8 360 9 5 V 2 6 V 8 2 7 V 8 4 5 10 30 cm 9 3 3 V 4 5 13 5 6 V 2...

Страница 142: ...142 2 2 11 11 3 4 bar 4 bar 8 2 8 10 12 mm 3 3 2 2 3 2 2 2 3 2 11...

Страница 143: ...143 9 11 11 2 45 3...

Страница 166: ...166 RU W rth 3 3 1...

Страница 167: ...167 18 16 8...

Страница 169: ...169 2 2 V 3 3 V 11 9 3 4 V 2 9 8 360 9 5 V 2 6 V 8 2 7 V 8 4 5 III 10 30 9 3 3 IV 4 5 13 5 6 V 2 9 8 1 V...

Страница 170: ...170 2 2 11 11 3 4 4 8 2 8 10 12 3 3 2 2 3 2 2 2 3 2 11...

Страница 171: ...171 9 11 11 2 45 3...

Страница 173: ...173...

Страница 174: ...174...

Страница 175: ...175...