Cordless chain saw

EN

15

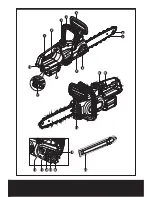

ASSEMBLY

WARNING! Do not install the

battery pack before it has been

completely assembled.

Always wear gloves when handling the

bar and chain. These components are

sharp and may contain burrs.

CHAIN AND GUIDE BAR ASSEMBLY

1. Unpack all parts carefully.

2. Place the chain saw on a solid, level surface.

3. Use only genuine WORX chains or those

recommended for guide bar.

4. Slide the chain (7) in the slot around the

guide bar (6). Ensure the chain is in correct

running direction by comparing it to the

chain icon on the guide bar, or referring to

the chain direction symbol (17) found on

the saw body. Ensure the bar tensioning

plate (23) is facing outward. (See Fig. A1)

Recommendation: If you find it is hard for

you to assemble the chain smoothly into

the groove of the bar, then you can try

the way as it shown in Fig A2: to hold the

bar vertically and slide the chain from the

top of the bar. It will help you to smoothly

assemble the chain easier.

5. Fit the chain onto the drive sprocket (16), so

that the fastening bar hole (20) and the two

bar locating tabs (21) on the bar pad (19)

fit into the keyway of the opening on the

guide bar (6). (See Fig. B1, B2)

6. Assure all parts are seated properly. Make

sure the drive links are fully seated in the

drive sprocket (See Fig. C1), avoiding a kink

as shown in Fig. C2. If kink occurs, pick up

on the chain at the guide bar just ahead of

the kink and then pull the kink out.

NOTE:

Chain should rotate freely and be

free of kinks.

7. Fit the chain cover (9) exactly onto the tool,

and tighten the chain cover by turning the

chain tensioning knob (8) clockwise until it

is tight. (See Fig. D)

WARNING: The chain is not

yet tensioned. Tensioning the

chain applies as described under

“TENSIONING CHAIN”. The chain now

needs to be inspected to make sure it is

properly tensioned.

TENSIONING CHAIN (See Fig. E1, E2)

NOTE:

New saw chains will stretch. Check

the chain tension frequently when first used

and tighten when the chain (7) becomes loose

around the guide bar (6).

WARNING:

●

Removing the battery pack before adjusting

saw chain tension.

●

Cutting edges on chain are sharp. Use

protective gloves when handling chain.

●

Maintain proper chain tension always.

A loose chain will increase the risk of

kickback. A loose chain may jump out of

guide bar groove. This may injure operator

and damage chain. A loose chain will cause

chain, bar, and sprocket to wear rapidly.

1. Place the chain saw on any suitable flat

surface.

2. Turn the chain tensioning knob (8)

clockwise until it is hand tight.

NOTE:

The tension is automatically

increased while the chain tensioning knob

(8) is being turned in a clockwise direction.

The built-in ratchet mechanism prevents

the chain tension from loosening.

3. Tilt the saw forward (See Fig. E1) where

the guide bar (6) tip is pushed in an upward

direction. This will remove slack from the

chain.

4. Fully tighten the chain tensioning knob (8)

by turning it clockwise.

5. Double check the tension set by the

automatic chain tensioning knob. The

correct chain tension is reached when the

chain (7) can be raised approx. half the

drivelink depth from the guide bar (6) in the

center. This should be done by using one

hand to raise the chain against the weight

of the machine. (See Fig. E2)

NOTE:

The chain (7) is properly tensioned

when it can be lifted off of the guide bar

(6) and the drivelink is within the rail of the

guide bar (6).

NOTE:

The chain (7) will stretch while

cutting and lose proper tension. When the

chain becomes loose, completely unscrew

the chain tensioning knob (8) or turn the

knob around three full turns in a counter-

Содержание WG380

Страница 2: ......

Страница 3: ...18 12 16 17 19 21 20 22 11 1 2 4 5 3 6 7 9 8 10 13 14 15 ...