6

23

SAFETY INSTRUCTIONS

(continued)

OPERATIONAL SAFETY (continued)

Completely engage load before lifting. Fork length should be at least two-thirds of load length. It is recommend-

ed to keep lifting surface of the forks level at all times. When backward tilt is required to stabilize the load, use

extreme caution.

Keep alert and watch the rear as well as the front when working with the loader. Beware of lift clearance when

raising loader to maximum height.

Beware of low electrical wires when loader is raised. Serious injury or death can result if contact is made.

Before you operate any equipment, check over all pins, bolts and connections to be sure all are securely in

place. Replace any damaged or worn parts immediately.

Do not work under a raised loader unless it is securely blocked or held in position. Do not depend on the power

unit hydraulic system to hold the implement in place.

Use extra care when using 48” or 60” forks. The forks may extend beyond what you are handling causing dam-

age or tip material on the other side.

Operate the loader controls smoothly, avoiding jerky operation. Stop loader gradually when lowering or lifting

loads.

When handling material on a slope, always approach the material with the power unit facing uphill.

Do not lift round bales.

When stacking material, ALWAYS MAKE SURE MATERIAL IS PLACED SO THE STACK IS STABLE.

Keep all bystanders at a safe distance. REMEMBER FALLING ITEMS CAN ROLL OR TUMBLE.

Do not handle loads that exceed the weight limitations of the loader or forks.

Carry the loads slowly and as low as possible to the ground. Avoid excessive speed during operation.

Do not allow children or others to ride on the power unit with an operator. Riders are subject to injury such as

being struck by foreign objects or being thrown off. Riders obstruct the operator’s view resulting in unsafe oper-

ation. Never allow anyone to ride on the implement!

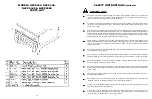

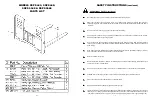

MODELS SSPF-3748, SSPF-3755 & SSPF-3760

PARTS LIST