24

5

SAFETY INSTRUCTIONS

(continued)

OPERATIONAL SAFETY

Be sure power unit is in good condition. Read all the safety precautions and make sure all operators are famil-

iar with the safety rules of operation.

Never leave the prime mover and implement unattended while the implement is in the lifted position. Accidental

operation of lifting lever or a hydraulic failure may cause sudden drop of unit with injury or death by crushing.

Keep all helpers and bystanders twenty-five feet (25’) from an operating power unit and attached equipment.

Only properly trained people should operate this machine. It is recommended the tractor be equipped with a

Rollover Protection System (ROPS) and a seat belt that is used. Always stop the tractor, skid steer, or forklift,

set brake, shut off the engine, remove the ignition key, and lower loader and attachment to the ground before

dismounting. Never leave equipment unattended with the engine running.

Please remember it is important that you read and heed the safety signs on the front loader attachment and

loader, and the safety rules set forth. Clean or replace all safety signs if they cannot be clearly read and under-

stood. They are there for your safety as well as the safety of others. The safe use of this machine is strictly

up to you, the operator.

The use of any loader attachment is NOT recommended on tractor with a tricycle wheel arrangement. Tricycle

type tractors are unstable for front loader use.

A heavy load can cause instability in driving a power unit. Make sure the front or rear of the power unit is

properly counter-balanced with weights. Always drive slowly – especially around turns. An unstable power unit

could steer badly and possibly tip over, causing injury or death.

Never allow children to play on or around prime mover or implement. Children can slip or fall off the equipment

and be injured or killed. Inadvertent contact with controls can cause the implement to shift or fall crushing them-

selves or others.

Always use two people to handle heavy, unwieldy components during assembly, installation, removal, or

moving the loader attachment.

Never place any part of your body where it would be in danger if movement should occur during assembly,

installation, operation, maintaining, repairing, removal, or moving the implement.

Start prime mover only when properly seated in the operator’s seat. Starting a prime mover in gear can result

in injury or death. Do not mount or dismount while the prime mover is moving. Mount or dismount only when

the prime mover and all moving parts are completely stopped.

Operate the prime mover and/or implement controls only while properly seated in the prime mover’s seat with

the seat belt securely fastened around you. Inadvertent movement of the tractor or implement may cause

serious injury or death.

Check that this attachment is securely mounted to the loader. Failure to install lock pins or have the latching

mechanism engage could result in injury or death.

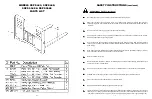

MODELS GLPF-442, GLPF-448,

GLPF-5448 & GLPF-5560

PARTS LIST