SERVICE AND SPARES

6 720 804 532 (2012/09)

34

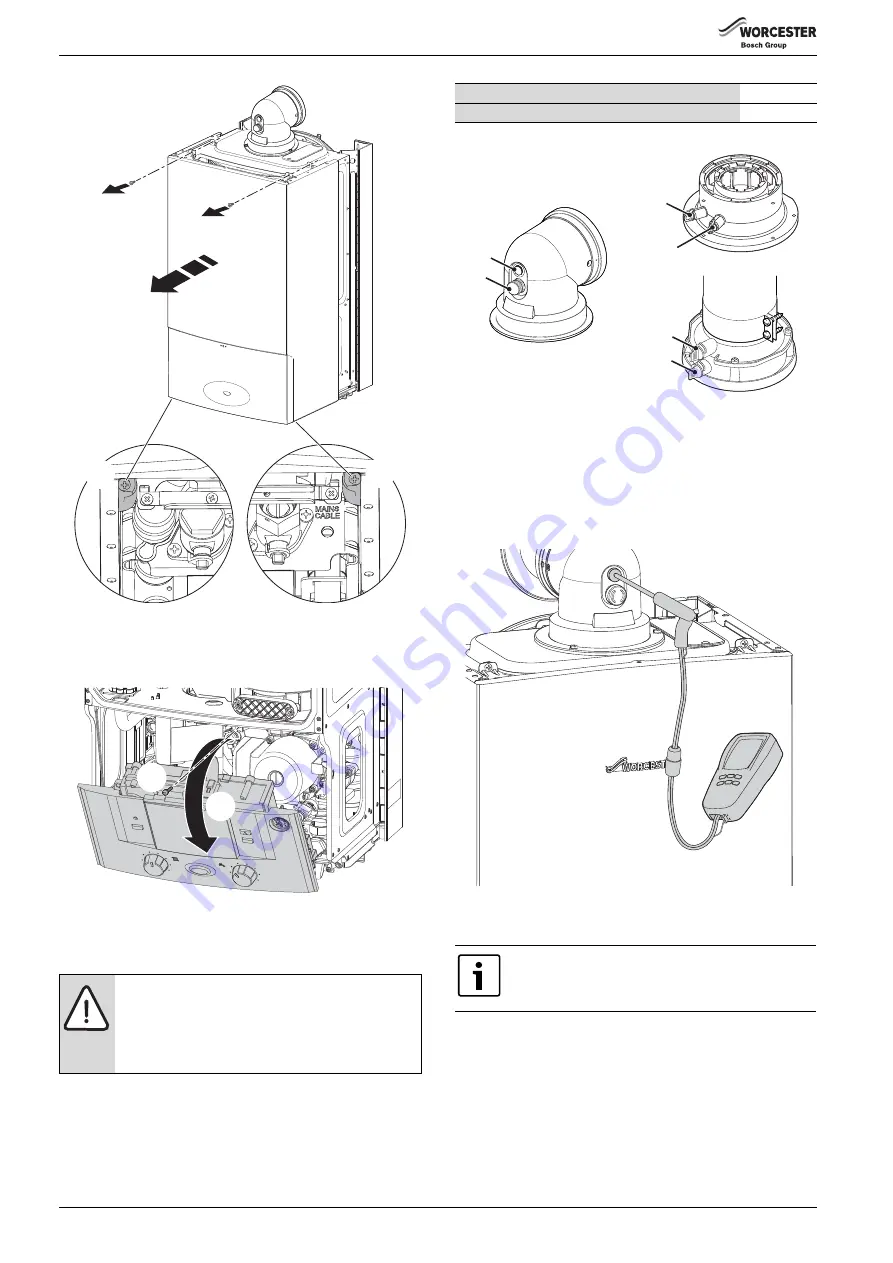

Fig. 70 Remove outer case

2. Lowering boiler control to the service position:

– Remove screw (1) securing the control panel.

– Pull the panel (2) forward into the service position.

Fig. 71 Moving control panel into the service position

6.2

CHECK THE GAS INLET PRESSURE

Refer to section 5.5.1 for checking the gas inlet pressure.

6.3

CHECKING FLUE INTEGRITY

The integrity of the flue system and performance of the boiler can be

checked via the flue turret sample points.

Fig. 72 Flue test points

▶ With the boiler case on and the boiler running at maximum.

▶ Insert the analyser probe into the air intake test point.

▶ Allow the readings to stabilise and check that:

– O

2

is equal to, or greater than 20.6%

– CO

2

is less than 0.2%

▶ If the readings are outside these limits then this indicates that there is

a problem with the flue system or combustion circuit.

Fig. 73 Flue integrity test

6.4

FAN PRESSURE TEST

SETTING THE BOILER TO MAXIMUM

1. Press and HOLD service button for more than 10 seconds

2. Set the Central Heating temperature to maximum.

– The service button will illuminate continually and the blue power

indicator will pulse 5 times.

– The boiler will stay in this mode for 15 minutes unless the service

button is pressed again.

NOTICE:

▶ Ensure that the gas inlet pressure is satisfactory with

all other gas appliances working.

▶ Do not continue with the other checks if the correct

gas inlet pressure can not be achieved.

1.

1.

2.

2.

6720643895-57.1W

o

1.

2.

6720644743-18.1Wo

Flue gas sample point

1

Air inlet sample point

2

Table 19 Key to figure 72

This test is to

determine if the heat cell requires

cleaning/attention.

2

1

2

2

1

1

6720643895-67.1Wo

6720643895-104.1W

o