Dealer Check Lists

27

MAN0999 (12/4/2012)

DEALER CHECK LISTS

PRE-DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY

)

Inspect the equipment thoroughly after assembly to

make sure it is set up properly before delivering it to the

customer. The following check list is a reminder of

points to inspect. Check off each item as it is found sat-

isfactory, corrections are made, or services are per-

formed.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check that all shields and guards are properly

installed and in good condition. Replace if dam-

aged.

___ Properly attach implement to power unit and

make all necessary adjustments.

___ Check all bolts to be sure they are properly

torqued.

___ Check that all cotter pins and safety pins are

properly installed. Replace if damaged.

___ Check and grease all lubrication points.

___ Check the level of gearbox fluids before delivery.

___ Run unit immediately following set-up to double-

check systems operation including hydrostatic

neutral and safety switch system (page 11).

___ Check all fluid levels. See Lubrication, page 25.

___ Check tire pressure. See Drive Tire Pressure,

page 25.

DELIVERY CHECK LIST

(DEALER’S RESPONSIBILITY)

___ Show customer how to make adjustments.

___ Instruct customer how to lubricate and explain

importance of lubrication.

___ Point out the safety decals. Explain their meaning

and the need to keep them in place and in good

condition. Emphasize the increased safety haz-

ards when instructions are not followed.

___ Present Operator's Manual and request that cus-

tomer and all operators read it before operating

equipment. Point out the manual safety rules,

explain their meanings, and emphasize the

increased safety hazards that exist when safety

rules are not followed.

___ Show customer how to make sure driveline is

properly installed and that spring-activated lock-

ing pin or collar slides freely and is seated in

groove on power unit PTO shaft.

___ Show customer the safe, proper procedures to be

used when mounting, dismounting, and storing

equipment.

___ Make customer aware of optional equipment

available so that customer can make proper

choices as required.

❖

Содержание MOW'N MACHINE FZ22K

Страница 1: ...OPERATOR S MANUAL MOW N MACHINE MAN0999 Rev 11 7 2013 FZ22K TM...

Страница 28: ...28 Dealer Check Lists MAN0999 12 4 2012 NOTES...

Страница 30: ...30 Parts MAN0999 12 4 2012 FZ22K FRAME ASSEMBLY Rev 2 18 2013...

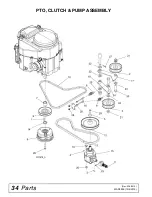

Страница 34: ...34 Parts MAN0999 12 4 2012 PTO CLUTCH PUMP ASSEMBLY Rev 2 18 2013...

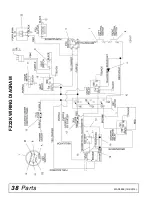

Страница 38: ...38 Parts MAN0999 12 4 2012 FZ22K WIRING DIAGRAM...