HM126 Operator’s Manual

TROUBLESHOOTING

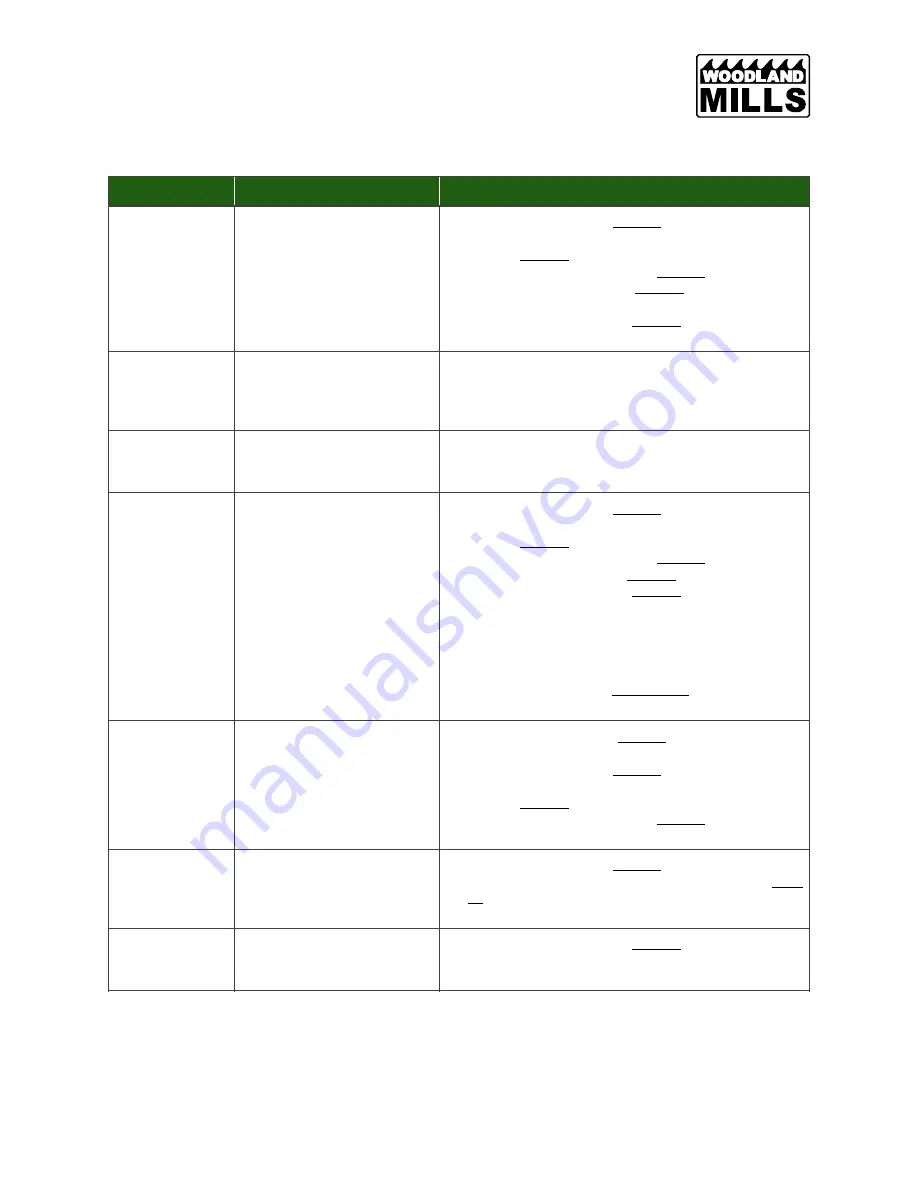

Problem/Issue

Possible Causes

Resolution Options

Producing wavy

cuts

1. Inadequate blade tension.

2. Improper blade guide set

up.

3. Improper blade tracking.

4. Sap build up on blade.

5. Dull blade.

6. Pushing mill too quickly.

1. Tighten blade. Refer to page 70.

2. Gap between guide blocks and blade are incorrect.

Refer to page 78.

3. Adjust blade tracking. Refer to page 73.

4. Install new blade. Refer to page 83.

Always use blade

lubricant.

5. Install new blade. Refer to page 83.

6. Slow feed rate down and push head slower through log.

Last board is

tapered or

narrow in middle

1. Track is not level.

1. Track needs to be checked for level and adjusted so it

is square. Track should also be set up on a firm, sturdy

base so deflection does not occur from heavy logs or

the sawmill head.

Blade dulls

quickly

1. Logs are not clean.

2. Foreign objects in log.

1. Logs may contain dirt/sand causing blades to wear

prematurely.

2. Tree may contain nails, staples, old fencing etc.

Blade comes off

band wheels

1. Inadequate blade tension.

2. Improper blade guide set

up.

3. Improper blade tracking.

4. Belts are worn.

5. Dull blade.

6. Pushing mill too quickly.

7. Too much water on blade.

8. New belts not dressed.

9. Belt tensioner idler pulley

not adjusted properly.

1. Tighten blade. Refer to page 70.

2. Gap between guide blocks and blade are incorrect.

Refer to page 78.

3. Adjust blade tracking. Refer to page 73.

4. Install new belts. Refer to page 84.

5. Install new blade. Refer to page 83.

6. Slow feed rate down and push head slower through log.

7. Valve on water tank is letting out too much water.

Reduce flow by turning dial on valve.

8. Run the sawmill without lubrication for 30 minutes in

order to dress new belts sufficiently before adding water

for lubrication. Refer to page 66 (#3).

9. Call Woodland Mills Technical Support.

Blades are

breaking

1. Too many blade

sharpenings.

2. Inadequate blade tension.

3. Improper blade guide set

up.

4. Improper blade tracking.

5. Pushing mill too quickly.

1. Replace blade. Refer to page 83.

2. Binding between guide blocks when blade is too loose.

Tighten blade. Refer to page 70.

3. Gap between guide blocks and blade are incorrect.

Refer to page 78.

4. Adjust blade tracking. Refer to page 73.

5. Slow feed rate down and push head slower through log.

Blade is slowing

down or

stopping when

milling

1. Inadequate blade tension.

2. Improper drive belt tension.

3. Pushing mill too quickly.

1. Tighten blade. Refer to page 70.

2. Belts are worn or too loose. Replace. Refer to page

3. Slow feed rate down and push head slower through log.

Mill is not cutting

or cutting very

slowly

1. Dull blade.

2. Blade is on backwards.

1. Install new blade. Refer to page 83.

2. Remove blade and flip it inside out. The teeth should

be facing in the direction of the log supports.

HM126-MY2021-EN: Rev F

Page

of

87

112

14-Jul-2021

Содержание HM126

Страница 2: ...This page intentionally left blank ...

Страница 114: ...HM126 Operator s Manual NOTES HM126 MY2021 EN Rev F Page of 112 112 14 Jul 2021 ...

Страница 115: ...This page intentionally left blank ...

Страница 116: ......