8

3060918_1203

Installation

The ventilation air supply must

be ensured and comply with

local regulations or those re-

lating to gas installations. We

recommend that you supply the

boiler with fresh air directly from

the outside. An insufficient fresh

air supply can lead to

fuel gas

escaping, which represents

a risk to life (poisoning/suf-

focation)

.

Clearances towards walls and

combustible materials must

comply with local fire regula

-

tions, and should be at least

200mm, otherwise there is a

high risk of fire

.

General tips regarding location

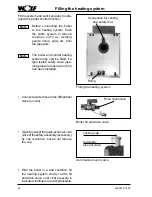

• Install the boiler with or without the

DHW cylinder on a level surface which

is substantial enough to carry its weight.

• Position the boiler and DHW cylinder (if

installed) horizontally or slightly rising

towards the back to ensure adequate

venting of any trapped air (level with

adjustable feet).

Only install the boiler and DHW

cylinder (if installed) in a room

safe from the risk of frost.

Drain the boiler, the DHW

cylinder and the entire heating

system if there is a risk of frost,

when the system has been

shutdown, to prevent pipes

from bursting.

Boilers should not be installed

in areas subject to aggressive

vapours, very dusty or highly

humid conditions (workshops,

washrooms, hobby rooms etc.).

This prevents the optimum

burner function from being

achieved.

The combustion air supplied to

the pressure jet oil burner must

be free from halogenated hy-

drocarbons (e.g. as contained

in sprays, solvents, cleaning

fluids, paints and adhesives).

Under the most unfavourable

conditions, these may lead to

pitting of the boiler and even

the flue gas system.

Never store or use combustible

material or liquids near the

boiler.

Note

Note