15

Tool holders

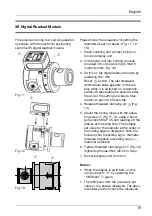

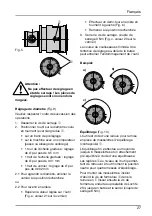

(Fig. 2)

Mounting

The tool holders

6

are fastened on a

clamping surface using a threaded taper

pin

5

in the slider.

Serrated tool bodies and insert holders

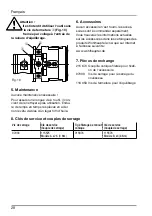

(Fig. 3)

Mounting

The serrated tool bodies

7

are fastened

in the slider using a threaded taper pin

5

.

To fasten the insert holders

8

in place,

they are mounted onto the K-profi le of the

serrated tool body and clamped using the

fi xing screw

9

(tightening torque 8 Nm

(70.81 in. lbs.)). The insert holders can be

preset using the scale on the serrated tool

body and insert holders. The scale on the

insert holder is valid for a center slider

position (= 0).

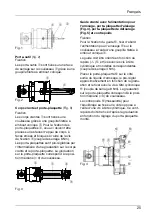

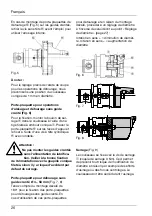

Serrated slide with coolant delivery

section, insert holder for boring (Fig. 4),

insert holder for outside turning (Fig. 5)

and counterweight

Mounting

To fasten the serrated slide

0

the coolant

delivery section 11 is fastened using a

threaded taper pin

5

in the slider.

The serrated slide is aligned according to

the marking ( )

“

and fastened in place

using the cap screws with washer. (tighte-

ning torque 4 Nm (35.40 in. lbs.)).

Insert holder

„

is mounted on the side with

the coolant delivery section, roughly preset

according to the scale and then fastened

in place using cape screw

”

(tightening

torque 8 Nm (70.81 in. lbs.)). The scale on

the insert holder is valid for a center slider

position (= 0).

The balancing counterweight

¿

is fastened

on the opposite side using a cap screw.

This counterweight must be fastened in

place to match the scale setting for the

mounted insert holder.

English

Fig. 1

Fig. 2

Fig. 3

Fig. 4

3

4

5

5

7

5

8

9

6

5

0

ß

„

”

“

¿

Содержание VARIOBORE 536

Страница 1: ......