Limited Lifetime Warranty

This Wirepath Product has a Lifetime Limited Warranty. This warranty includes parts and labor repairs on all components found to be defective in

material or workmanship under normal conditions of use. This warranty shall not apply to products that have been abused, modified, or disassembled.

Products to be repaired under this warranty must be returned to SnapAV or a designated service center with prior notification and an assigned return

authorization number (RA).

Lifetime

Rev:

200908

-

0843

www.snapav.com Support: 800.838.5052

Hinged Doors

Flush Mount Doors

Dimensions

WP-DOOR-HINGE-14 — 15.35”W x 15.12”H x 0.25”D

WP-DOOR-HINGE-20 — 15.35”W x 21.1”H x 0.25”D

WP-DOOR-HINGE-28 — 15.35”W x 29.1”H x 0.25”D

WP-DOOR-HINGE-40 — 15.35”W x 41.10”H x 0.25”D

WP-DOOR-FLUSH-14 — 15.35”W x 15.12”H x 0.25”D

WP-DOOR-FLUSH-20 — 15.35”W x 21.1”H x 0.25”D

WP-DOOR-FLUSH-28 — 15.35”W x 29.1”H x 0.25”D

WP-DOOR-FLUSH-40 — 15.35”W x 41.10”H x 0.25”D

Installation Screws WP-DOOR-HINGE-14 — 4 screws

WP-DOOR-HINGE-20 — 4 screws

WP-DOOR-HINGE-28 — 8 screws

WP-DOOR-HINGE-40 — 8 screws

WP-DOOR-FLUSH-14 — 4 screws

WP-DOOR-FLUSH-20 — 4 screws

WP-DOOR-FLUSH-28 — 4 screws

WP-DOOR-FLUSH-40 — 4 screws

Keys

Yes (2)

N/A

UL Certified

Yes

Yes

Steel Gauge

20

20

Color

White Powder Coat Finish

White Powder Coat Finish

Dual Locking

Yes

N/A

Doors

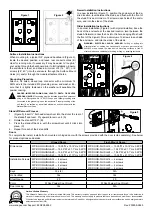

A

C

B

B

H

!

!

WARNING: ELECTRICAL SHOCK HAZARD!

Cutting or drilling into

electrical wires or cables can cause death or serious personal injury!

ALWAYS make certain the area behind mounting surfaces is free of

electrical wires and cables before cutting, drilling, or installing fasteners.

DANGER: IMPROPER WIRING CAN LEAD TO DEATH OR SEVERE

PERSONAL INJURY!

Grounding must be installed by qualified personnel

using a UL Recognized No. 12 AWG Green and Yellow grounding wire

connected to the grounding lug on the enclosure. Proper grounding of the

unit should be verified by a

q

u

a

lified electrician and compliant with the

National Electrical Code.

Newer Installation Instructions

In a new installation (Figure 1), position the enclosure at the de

-

sired location, level between the studs, and flush with the front of

the studs. Drive a minimum of 2 screws in each side of the enclo

-

sure, and into the sides of the studs.

Older Installation Instructions

In an older installation (Figure 2) with drywall installed, trace the

back of the enclosure at the desired location, level between the

studs. Afterward, recess the box into the hole, keeping it flush with

the front of the drywall. Drive a minimum of 2 screws in each side

of the enclosure, and into the sides of the studs.

Surface Installation Instructions

When mounting to a typical 3/4” plywood backboard (Figure 3),

locate the desired position, and leave rear conduit entries (B)

clear for running wire, if necessary. It may be easier to “rough-in”

your wiring through the backboard prior to full installation. Ensure

the enclosure is level, and drive a minimum of 4 (14”, 20”), or 6

screws (28”, 40”) into the enclosure through the Surface Mount

Holes (H), and/or through the module attachment holes.

Grounding Procedure

Attach a UL listed, closed loop connector with a minimum 12

AWG wire to the included M5 grounding screw and washer. En

-

sure that it is tightly fastened so the washer will penetrate the

powder coating.

Figure 1

Figure 2

Figure 3

Figure 5

1. (Figure 5) Insert ¼” flat head screwdriver into the slot at the rear of

the standoff and twist. Pry upward to remove it. (A)

2. Rotate the standoff 180°. (B)

3. Press the standoff back in with the screwdriver until it clicks into

place. (C)

4. Repeat for each of the 4 standoffs.

Standoff Removal Process

To complete the install, install a flush mounted or hinged door with the screws provided with the door (sold separately). See below

for product options and details.

Figure 4