GROUNDING & OPERATION

98330 03/28/00

4

INSPECTION

Carefully unpack and inspect your mini-

extractor for shipping damage. Each unit is

operated and thoroughly inspected before

shipping and any damage is the responsibility

of the carrier, who should be notified

immediately.

GROUNDING INSTRUCTIONS

This appliance must be grounded. If it should

malfunction or breakdown, grounding provides

a path of least resistance for electric current to

reduce the risk of electric shock. This

appliance is equipped with a cord having an

equipment-grounding conductor and grounding

plug. The plug must be inserted into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes

and ordinances.

This appliance is for use on a nominal 120-volt

circuit, and has a grounded plug that looks like

the plug in “Fig. A”. A temporary adaptor that

looks like the adaptor in “Fig. C” may be used to

connect this plug to a 2-pole receptacle as

shown in “Fig. B”, if a properly grounded outlet

is not available. The temporary adaptor should

be used only until a properly grounded outlet

(Fig. A) can be installed by a qualified

electrician. The green colored rigid ear, lug, or

the like extending from the adaptor must be

connected to a permanent ground such as a

properly grounded outlet box cover. Whenever

the adaptor is used, it must be held in place by

a metal screw.

EXTENSION CORDS

If an extension cord is used, the wire size must

be at least one size larger than the power cord

on the machine. This mini-extractor is

equipped with a 25 ft. 16/3 power cord.

Do not exceed the 50-ft. cord limit.

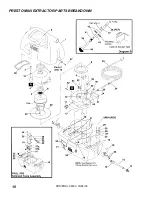

A. SET UP AND OPERATION

1.

Upon removing your new mini-extractor

from the box, loosen the two latches at

either end of the machine that secure the

recovery tank to the solution tank. Remove

the recovery tank from the solution tank.

2.

Pour up to 2 U.S. gallons (7.6 liters) of

clean, hot water into the blue solution tank.

To avoid possible tank distortion, water

temperature must not exceed 140 F

(60C).

3.

Add a non-foaming cleaning solution

concentrate, for use in hot water extractors

at the proportions noted on the container

(See list below), into solution tank.

4.

Place the recovery tank back onto the

solution tank and refasten the two latches.

5.

Plug the power cord into grounded outlet

(See GROUNDING INSTRUCTIONS).

6.

Connect the vac and cleaning tool hoses to

the extractor. Insure that the female

solution hose coupler is securely locked

onto the male coupler on the extractor.

WARNING! To prevent possible disease

hazard, before attempting to clean bodily

fluids spills, you must kill any viruses,

germs or bacteria present in the bodily fluid.

SUITABLE

INCOMPATIBLE

CHEMICALS

CHEMICALS

Alkalis

Aldehydes

Clorox II Bleach*

Aromatic Hydrocarbons

Defoaming Agents

Butyls

Detergents

Carbon Tetrachloride

Hydroxides

Clorox*

Oxygen Bleaches

Chlorinated Bleaches

Soaps

Chlorinated

Hydrocarbons

Sta-Puf Fabric

D-Limonene

Softener*

Lysol*

Vinegar

Methyls (MEK)

Perchlorethylene (perc)

Phenols

Trichlorethylene

*Registered Trademark