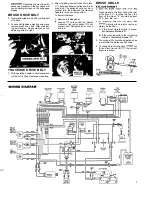

MAINTENANCE

1.

Keep tops of batteries clean and dry.

Use a damp cloth with a weak

of baking soda or ammonia and water.

Use a clean dry cloth to wipe battery

tops dry after cleaning.

2.

If corrosion (white deposits) appears on

the battery terminals and cable clamps,

remove and clean. Use a battery terminal

and connector cleaning tool.

BATTERY TERM

I

N

AL CLEAN E

2.

Check motor brushes

-

when worn to

length replace both brushes.

3.

Keep the battery electrolyte at the

correct level

-

approximately 114" below

bottom of filler tube of each cell. Dis-

tilled

water should be added, as needed,

AFTER

charging cycle.

WARNING:

Do not allow electrolyte

to drop below the tops of the plates.

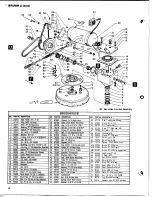

THE

SCRUBBER

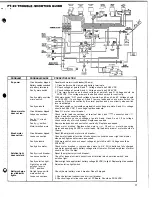

Before making any adjust-

ments or repairs to the machine..

.

1.

Only

maintenance personnel

are to perform repairs.

2.

Make sure battery charger is dlscon-

3.

Make sure all switches are

"OFF"

4.

Remove batteries as required or

nect main battery leads from batteries

when making repairs to electrical

VACUUM MOTOR

1.

Disconnect motor leads from connector

and

out

motor.

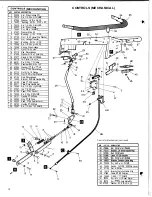

DRIVE CHAIN

1.

Remove left side skirt and side panel.

2. To remove chain, remove retaining clip

and pull out master link.

3.

To

adjust chain tension

. . .

A. Remove traverse drive pulley.

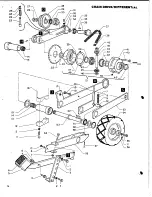

2.

Remove

to allow removal of left

3.

Remove

hand pivot bolt, bushing

hand lift arm.

and lift arm.

4.

To check gear

oil level

-

remove

Inspection plug;

should be at the

bottom of hole.

To add

remove fill

plug and add

90 welght oil as needed.

B.

Loosen

nut and back out screw

turn.

C.

Use a hammer and punch to rotate

the eccentric bushing to tighten or

loosen the drive chain.

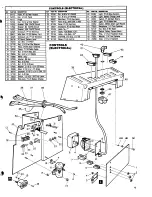

TRAVERSE DRIVE MOTOR

1.

Remove lower right hand

skirt.

2.

Disconnect motor leads from terminal

3.

Remove snap

from end of motor

pivot shaft.

QEAR

UNIT

1. Loosen belt tension screw and remove

belts.

5

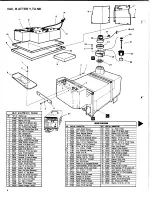

Содержание PowerTec20

Страница 1: ......

Страница 9: ...1 7 AI 1 6 9...

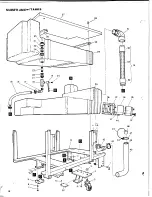

Страница 10: ...MAINFRAMEWITANKS 38 I 34 37 36 35 39 41 i o 1 3 14 1 46...

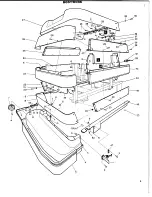

Страница 11: ...SQUEEGEE w ARM 59 69 21 1 I __ 11...

Страница 13: ...48 4 9 50...

Страница 14: ...14 2 1 IAL 39...