DS-459A REV DATE: 03-29-04

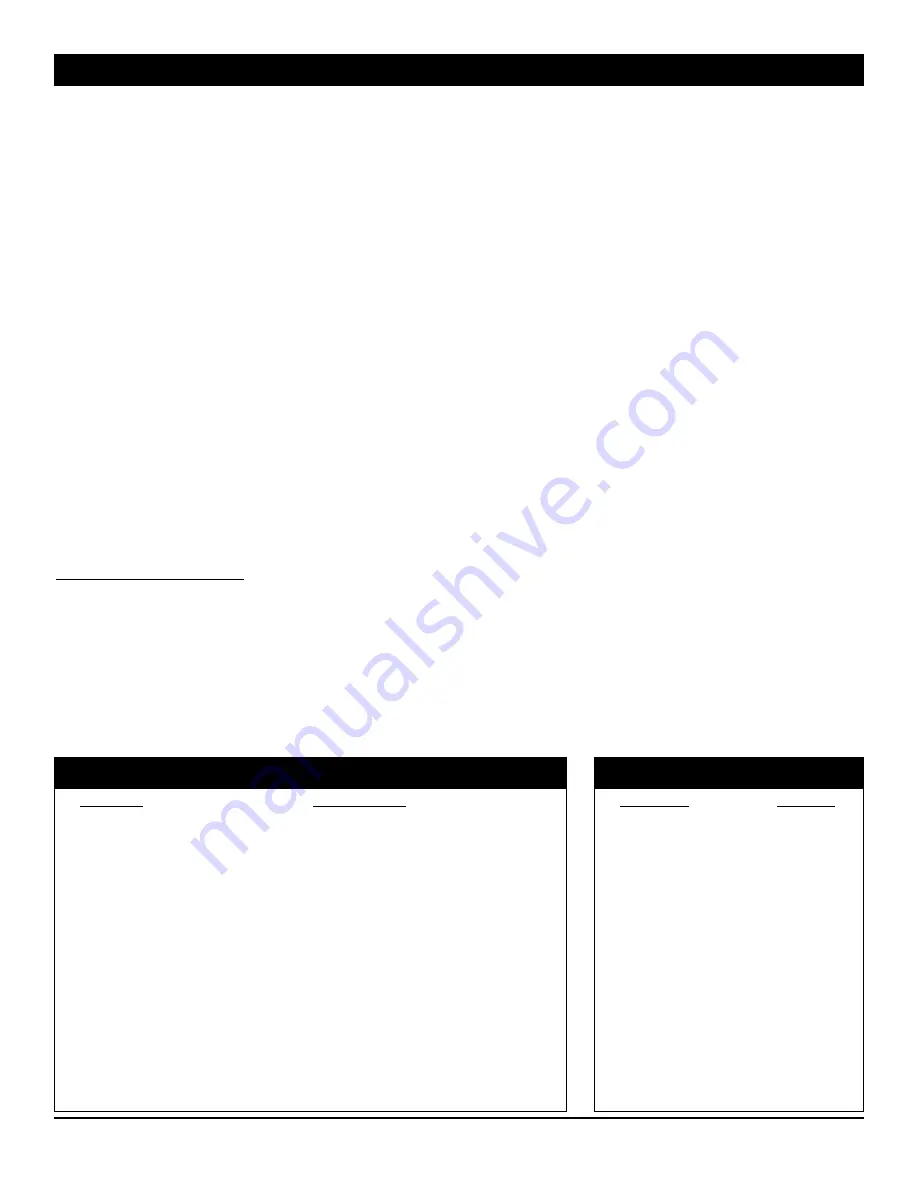

1/4-20

1/4-28

5/16-18

5/16-24

3/8-16

3/8-24

7/16-14

7/16-20

1/2-13

1/2-20

9/16-12

9/16-18

5/8-11

5/8-18

85 in-lb

103 in-lb

180 in-lb

198 in-lb

22 ft-lb

30 ft-lb

42 ft-lb

47 ft-lb

65 ft-lb

77 ft-lb

95 ft-lb

105 ft-lb

110 ft-lb

120 ft-lb

Bolt Torque Specifications

BOLT SIZE

TORQUE

NOTE: This bolt torque specification list is for

use with specific grades of bolts as supplied in

the particular Wilwood kit and is not intended

as a guide for any other application.

260-1874

260-1876

260-2220

290-0632

290-6209

340-1285

340-1287

260-6764

260-6765

260-6766

260-4893

250-2406

350-2038

270-2016

270-2017

220-0149

220-0842

Wilwood Residual Pressure Valve (2 lb for disc brakes)

Wilwood Residual Pressure Valve (10 lb for drum brakes)

Wilwood Proportioning Valve

Wilwood Racing Brake Fluid (Hi-Temp° 570) (12 oz)

Wilwood Racing Brake Fluid (EXP 600 Plus) (16.9 oz)

Wilwood Floor Mount Brake Pedal (with balance bar)

Wilwood Swing Mount Brake Pedal (with balance bar)

Wilwood 3/4 inch High Volume Aluminum Master Cylinder

Wilwood 7/8 inch High Volume Aluminum Master Cylinder

Wilwood 1 inch High Volume Aluminum Master Cylinder

1-1/16 inch Tandem Master Cylinder (aluminum housing)

Mounting Bracket Kit (tandem master cylinder)

1971 - 1973 Pinto Rack and Pinion (new, not rebuilt)

Quick Release Steering Hub (3/4 inch shaft)

Quick Release Steering Hub (5/8 inch shaft)

Fitting, Straight (1/8-27 NPT to -4)

Fitting, 90° Elbow (1/8-27 NPT to -4)

(Consult the Wilwood Catalog for a complete parts list)

Associated Components

Additional Information and Recommendations

PART NO.

DESCRIPTION

Wilwood Disc Brakes • 4700 Calle Bolero, Camarillo, CA 93012 Phone 805 / 388-1188 • Fax 805 / 388-4938

•Fill and bleed the new system with Wilwood Hi-Temp° 570 grade fluid or higher. For severe braking or sustained high heat operation,

use Wilwood EXP 600 Plus Racing Brake Fluid. Used fluid must be completely flushed from the system to prevent contamination.

NOTE: Silicone DOT 5 brake fluid is NOT recommended.

•To properly bleed the brake system, begin with the caliper farthest from the master cylinder. Bleed the outboard bleed screw first, then

the inboard. Repeat the procedure until all calipers in the system are bled, ending with the caliper closest to the master cylinder.

NOTE: When using a new master cylinder, it is important to bench bleed the master cylinder first.

•Test the brake pedal. It should be firm, not spongy and stop at least 1 inch from the floor under heavy load.

If the brake pedal is spongy, bleed the system again.

If the brake pedal is initially firm, but then sinks to the floor, check the system for fluid leaks. Correct the leaks (if applicable) and

then bleed the system again.

If the brake pedal goes to the floor and continued bleeding of the system does not correct the problem, a master cylinder with

increased capacity (larger bore diameter) may be required. Wilwood offers various lightweight master cylinders with large fluid

displacement capacities.

•NOTE: With the installation of after market disc brakes, the wheel track may change depending on the application. Check your wheel

offset before final assembly.

•If after following the instructions, you still have difficulty in assembling or bleeding your Wilwood disc brakes, consult your local chassis

builder, or retailer where the kit was purchased for further assistance.

PAD BEDDING PROCEDURE:

•Pump brakes at low speed to assure proper operation. On the race track, or other safe location, make a series of hard stops until some

brake fade is experienced. Allow brakes to cool while driving at moderate speed to avoid use of the brakes. This process will properly

burnish the brake pads, offering maximum performance.

www.wilwood.com