27

WIKA operating instructions Ultra High Purity transducer, model WUD-2x

11611057.05 08/2021 EN/DE

EN

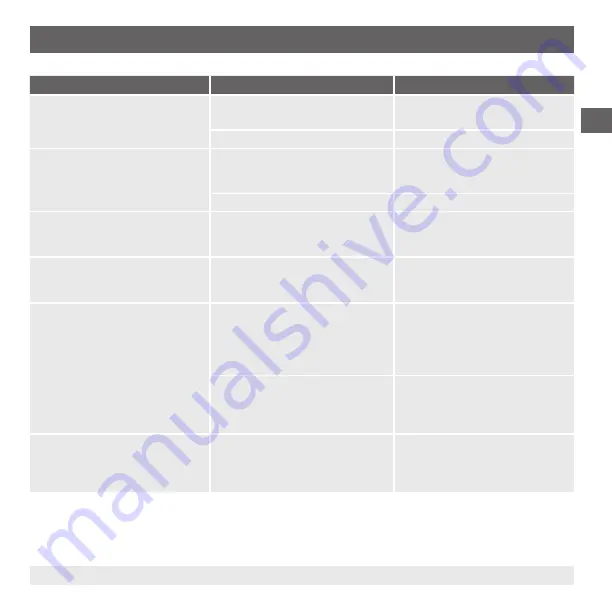

6. Faults

Failure

Possible cause

Procedure

Output signal unchanged after

change in pressure

Mechanical overload through

overpressure

Replace instrument; if failure

reoccurs, consult the manufacturer

1)

Wrong supply voltage or current spike Replace instrument

No output signal

No/incorrect voltage supply or current

spike

Adjust the voltage supply to corre-

spond with the Operating Instruc-

tions

1)

Cable break

Check connections and cable

No/False output signal

Incorrectly wired (e.g. Connected as

2-wire instead of 3-wire system)

Follow pin assignment (see

Instrument Label / Operating

Instructions)

Abnormal output signal or

abnormal zero point signal

Zero point set wrongly

Adjust zero point correctly (see

chapter 8); a sufficiently accurate

current/volt meter should be used

Abnormal zero point signal

Medium or ambient temperature too

high/too low

Control the internal temperature of

the instrument within the permis-

sible range; observe the allowable

temperature error (see Operating

Instructions)

Diaphragm is damaged, e.g. through

impact, abrasive/agressive media;

corrosion of diaphragm/pressure

connector.

Replace instrument

Signal span dropping off/too

small

Diaphragm is damaged, e.g. through

impact, abrasive/agressive media;

corrosion of diaphragm/pressure

connector

Contact the manufacturer and

replace the instrument