W10198666B

.

O

N

T

R

A

P

Y

L

N

O

E

S

U

S

’

N

A

I

C

I

N

H

C

E

T

E

C

I

V

R

E

S

R

O

F

TECH SHEET - DO NOT DISCARD

PAGE 2

B

Bu

utttto

on

n

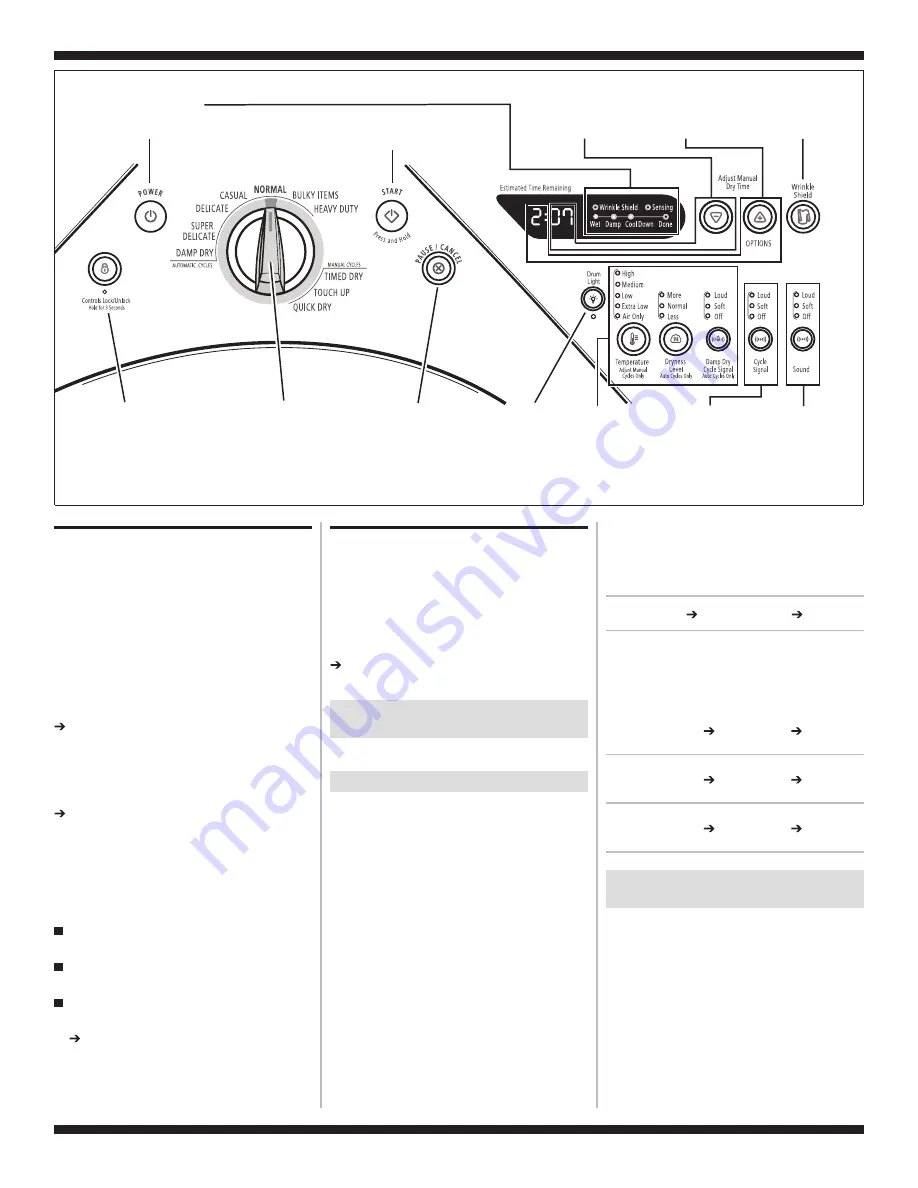

Rotating this Cycle

Selector turns cycle

LEDs on or off.

Start button controls its own indicator,

starts dryer, and displays version information.

Power button controls

its own indicator and

Cycle Status LEDs.

Controls Lock/Unlock button

controls LED below button.

Turns off all

LEDs and exits

diagnostics.

Drum Light button

controls LED

below button.

“Less Time” button

turns the middle and

right digit of the

display on or off.

“More Time” button

turns the left digit

and colon of the

display on or off.

Wrinkle Shield button

controls its own indicator

and starts Inlet

Air Flow Diagnostic.

Button Sound button

controls all LEDs

above button

(Green-Amber-Off).

Cycle Signal button

controls all LEDs

above button

(Green-Amber-Off)

and starts displaying

Line Voltage Diagnostic.

Each button

controls all LEDs

above button

(Green-Amber-Off).

Figure 1.

Console Diagnostics.

DIAGNOSTIC: Displaying Inlet Air Flow

(Electric Models Only)

Used to display the air flow value at the inlet

of the heater box being measured by the machine

control.

After entering the Diagnostic Test Mode, waiting

for the 5 second delay, and cycling through any

saved fault codes, press the Wrinkle Shield button

to activate air flow detection. A 30 or 50 second

countdown timer will start and the dryer will

turn on.

If the dryer is cold, the countdown will start

at 50 seconds.

NOTE:

If the dryer is extremely cold (less than

40°F [4.4°C]), the air flow may not be detected

properly, and “--” will be displayed.

If the dryer is hot, the countdown timer will

start at 30 seconds (cool down period),

followed by an additional 50 second

countdown.

A Dryness Level modifier LED will also be

illuminated to indicate the air flow range

corresponding to the number displayed.

The More LED will be illuminated for air flow

readings above 40 cfm.

The Normal LED will be illuminated for air flow

readings between 29 and 40 cfm.

The Less LED will be illuminated for air flow

readings less than 29 cfm.

If air flow value is low (Less LED is lit),

check to make sure the lint screen is clean,

the door seal is in place, and the vent is

not obstructed.

DIAGNOSTIC: Displaying Line Voltage

Used to display the line voltage currently being

measured by the machine control:

After entering the Diagnostic Test Mode, waiting

for the 5 second delay, and cycling through any

saved fault codes, press the Cycle Signal button.

The voltage value will be displayed.

If the line voltage is not seen on L2, the display

will flash

2

. Go to TEST #1, page 4.

DEACTIVATING THE DIAGNOSTIC

TEST MODE

Press the Pause/Cancel button to exit diagnostics.

ACTIVATING THE MANUAL LOAD TEST

1.

Be sure the dryer is in standby mode (plugged

in with all indicators off, or with only the Done

indicator on).

2.

Select any one button (except Pause/Cancel

and Controls Lock/Unlock) and follow the steps

below, using the same button (remember the

button):

a.

Press/hold 2 seconds

b.

Release for 2 seconds

c.

Press/hold 2 seconds

d.

Release for 2 seconds

e.

Press/hold 2 seconds

f.

Release for 2 seconds

g.

Press/hold 2 seconds

The motor starts right away, the “Sensing”

Status LED comes on, and “0” (zero) is

displayed (this step starts the Manual Load

sequence):

1.

Motor turns

on.

“Sensing” Status

LED turns on.

0:00 is

displayed.

Now press any key (except Pause/Cancel and

Controls Lock/Unlock) and the control will

advance through each step of the following

sequence:

2. Motor + heater.

“Damp”

Status LED

turns on.

0:02 is

displayed.

3.

Motor + heater

+ drum light.

“Cool Down”

Status LED

turns on.

0:03 is

displayed.

4.

All loads turn

off.

“Done”

Status LED

turns on.

0:04 is

displayed.

DEACTIVATING THE MANUAL

LOAD TEST

Press the Pause/Cancel button to exit this mode.

L