MAX Loaders

12

WESTENDORFMFG RR315270

Westendorf Manufacturing Co., Inc.

SECTION 3: MOUNTING / DISMOUNTING

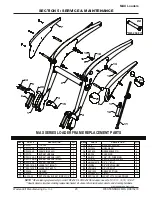

11. To relieve pressure

on Smart-Lock (D),

a p p l y d o w n - p r e s -

sure to the ground

with LIFT cylinders.

Press Smart-Lock

button (E) and flip

latches forward to

unlock loader from

tractor.

12. Extend LIFT cylinders

to pull upper tower

bushing (B) away

from bracket (C).

Continue

extending

cylinder, about 8” until

the indicator (F) slides

past the stop (G) and

tower is released.

13. SLOWLY retract

BUCKET cylinders

to raise loader

tower bushing (A)

from bracket. Once

released, loader arms

will settle back and

rest against bottom

of the bucket when in

the stored position.

E

D

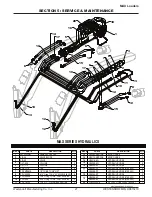

15. Place tractor transmission in park and relieve tractor

hydraulic pressure on LIFT CYLINDERS only.

See your tractor Operator’s Manual for correct procedure.

10. Fully dump loader

bucket and lower

arms to the ground

as shown.

WARNING!

Crushing

hazard. Prevent loader

from tipping by dismounting with approved bucket on

firm level surface. Detach loader on level surface. Keep

children and bystanders away from storage area.

Mounting

Bracket

Tower

B

C

Mounting

Bracket

Tower

A

14. SLOWLY back tractor

away--just enough to

clear lower receiver

on mounting bracket.

NOTICE! Watch hoses

while backing away!

Backing up too far will

pull or stretch the hoses

that are still connected

to the tractor.

WARNING!: Escaping fluid under pressure can

penetrate skin causing serious injury. Avoid hazard by

relieving pressure before connecting or disconnecting

pressure lines. Protect hands& body from high pressure

fluids. If injured seek immediate medical attention.

16. Disconnect

hoses and

electronic

circuit with

Hydra-Snap™.

See section 4

for operation.

17. Back away from loader.

F

G

Mounting

Bracket

Tower

Loader Dismounting

Содержание MAX420

Страница 1: ...1 Westendorf Manufacturing Co Inc WESTENDORFMFG RR315270 MAX Loaders MAX420 440 Max Loader...

Страница 23: ...23 Westendorf Manufacturing Co Inc WESTENDORFMFG RR315270 MAX Loaders SECTION 5 SERVICE MAINTENANCE...

Страница 35: ...35 Westendorf Manufacturing Co Inc WESTENDORFMFG RR315270 MAX Loaders NOTES...

Страница 36: ...MAX Loaders 36 WESTENDORFMFG RR315270 Westendorf Manufacturing Co Inc SECTION 5 SERVICE MAINTENANCE...