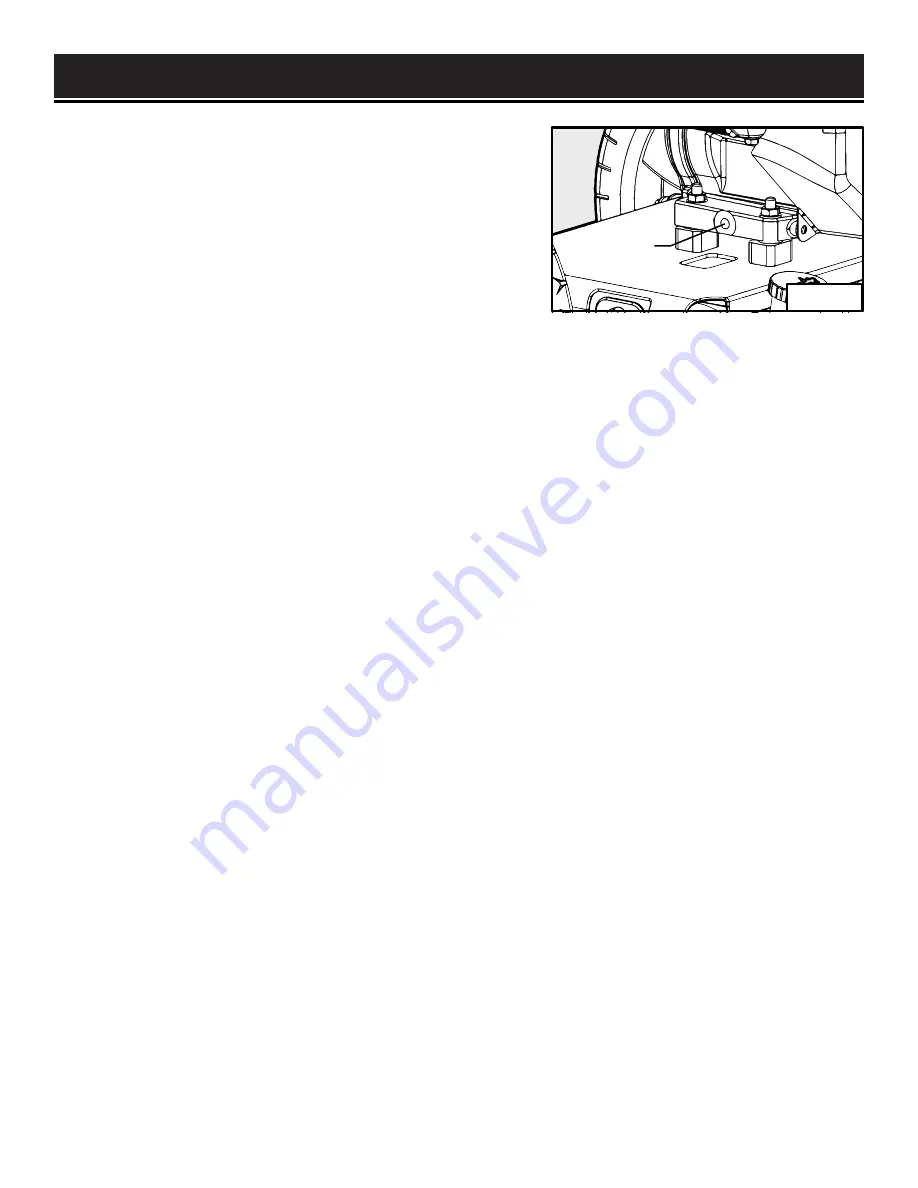

CHANGING/ADDING OIL (FIG. 16)

Change the oil according to the Recommended

Maintenance Schedule on page 17. Change the oil when

the engine is warm to allow for complete drainage.

Change oil more often if operating under heavy load or

high ambient temperatures. It is also necessary to drain

the oil from the crankcase if it has become contaminated

with water or dirt. The oil capacity of the pressure washer

engine is 15.3 fl oz (450 ml). Add oil when the oil level is

low. For proper type of oil refer to the “add oil” portion of

the “Preparation” section.

MAINTENANCE

Fig. 16

Oil Drain Plug

TO CHANGE OIL, FOLLOW STEPS BELOW:

1. Shut off engine. Clean the area around the oil fill cap/dipstick to keep out debris then remove oil

dipstick.

2. Place an oil pan on the ground to catch oil. Remove oil plug then tilt pressure washer back and to

the side to empty out the oil from the crankcase.

3. Once oil is completely drained, return the pressure washer to a level position and install the oil

drain plug. Refill the engine with new oil as instructed earlier in this manual under Adding/Checking

Oil.

AIR CLEANER MAINTENANCE

Routine maintenance of the air cleaner helps maintain proper airflow to the carburetor. Occasionally

check that the air cleaner is free of excessive dirt. Refer to Recommended Maintenance Schedule on

page 17.

1. Unscrew the cover bolt, then remove the air cleaner cover.

2. Remove the air cleaner element from the casing.

3. Check and clean the air cleaner element. Replace with a new one if the element is damaged. A

good element can be washed in soapy water and dried. Saturate the element with clean engine oil

and squeeze off excess oil.

4. Re-install the element. Wipe off excess oil from the air cleaner housing. A small amount of oil in

the element is normal and necessary for the engine to work properly.

5. Reinstall the air cleaner element and cover.

CAUTION:

running the engine with a dirty, damaged or missing air cleaner element will cause the

engine to wear out prematurely.

19