© Welding Industries Malaysia Sdn. Bhd. reserves all rights even in the event of industrial property rights. We reserve all rights of dis-

posal such as copying and passing on to third parties. Specification may vary from country to country. V1.1.06

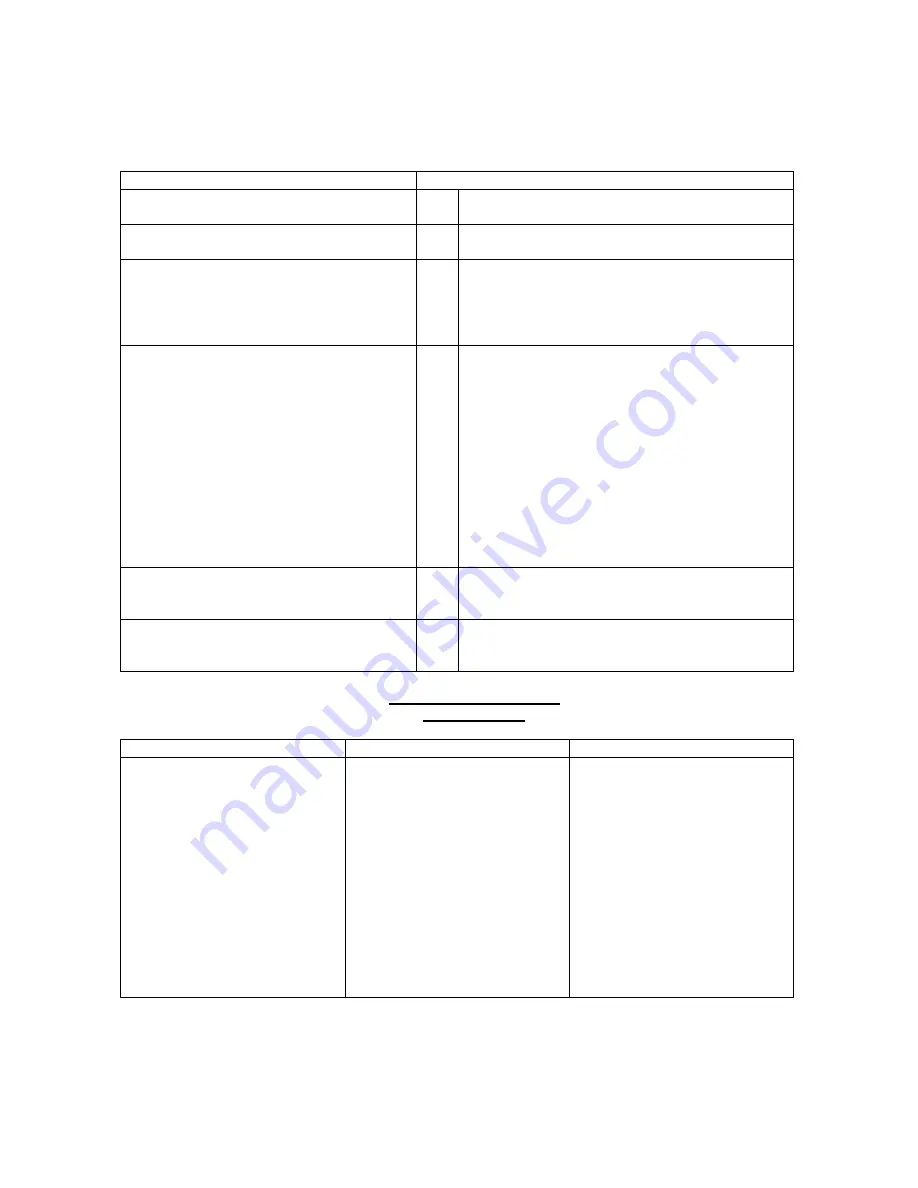

10.0 WELDING FAULTS

FAULT

POSSIBLE CAUSE AND REMEDY

1 Wel

d deposit ‘stringy’ and incomplete

1 a

1 b

Torch moved over workpiece too quickly

Gas mixture incorrect

2 Weld deposit too thick

2 a

2 b

Torch moved over workpiece too slowly

Welding voltage too low

3 Arc unstable excessive spatter and

weld porosity

3 a

3 b

3 c

Torch held too far from the workpiece

Rust grease or paint on workpiece

Insufficient shielding gas; check gas contents

gauge, regulator setting and operation of gas

valve

4 Wire repeatedly burns back

4 a

4 b

4 c

Torch held too close to the workpiece

Intermittent break in the welding circuit caused

by:

(1) Contact tip loose-tighten

(2) Contact tip damaged-replace

(3) Welding wire or liner corroded-replace

wire or liner

Wire feed slipping caused by:

(1) Restriction in liner (such as kinks) or

contact tip-check and replace if necessary

(2) Worn-out feed rolls-replace

(3) Guide tube or pressure roll alignments

incorrect.

5 Burning holes in the workpiece

5 a

5 b

5 c

Torch moved too slowly or erratically

Welding volts too high

Wire feed speed too high

6 Lack of penetration

6 a

6 b

6 c

Torch moved too fast

Welding volts too low

Wire feed speed too low

SHIELDING GAS TABLE

MIG WELDING

Metal

Gas

Remarks

Mild Steel

CO2

Argon + CO2

Argon + CO2 + Oxygen

Argon controls spatter

Oxygen improves arc stability

Aluminium

Argon

Argon Helium

Stable Arc-Sound welds

Higher heat input

Suitable for heavy sections

Stainless Steel

Argon + CO2 + Oxygen

Argon + Oxygen

Arc stability

Minimum spatter

Copper, Nickel and Alloys

Argon

Argon Helium

Suitable for light gauges

Higher heat input

Suitable for heavy sections