13

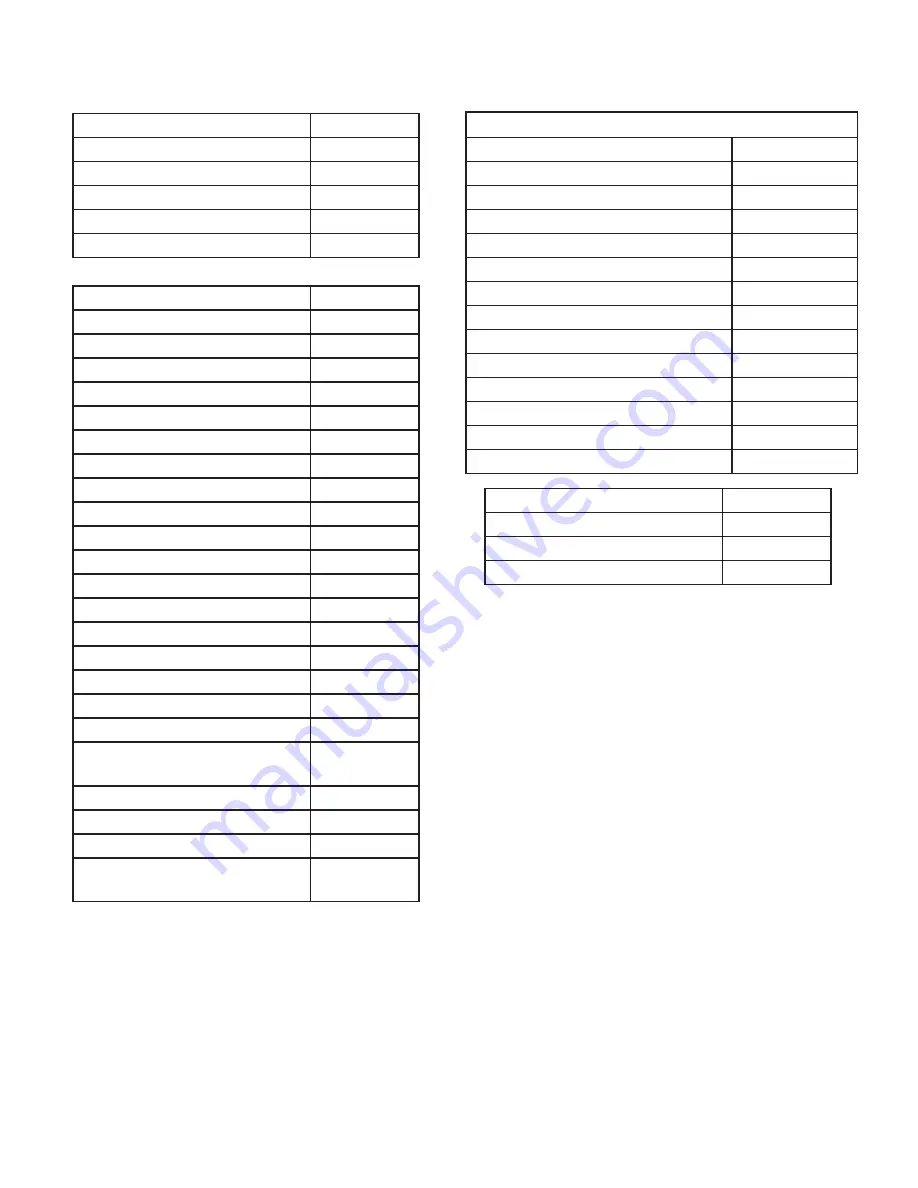

Section 5: QUICK REFERENCE CHART

Motor Options

1402

Wired for 115V, 60Hz, 1Ph

1402B-01

Wired for 230V, 60Hz, 1Ph

1402C-01

Wired for 230V, 50Hz, 1Ph

1402C-02

Wired for 230V, 60Hz, 3Ph

1402M-01

Wired for 230V, 50Hz, 3Ph

N/A

Specifi cations

Free Air Displacement, L/M (CFM)

160 (5.6)

Gas Ballast

Yes

Ultimate Pressure, Torr (mbar)

1 (1.3)x10-4

Rotational Pump (RPM)

525

Oil Capacity, quarts (Liters)

2.25 (2.1)

Net Wt. Unmounted Pump, lb (Kg)

82 (37)

Net Wt. Mounted Pump, lb (Kg)

112 (51)

Tubing Needed (I.D. Inches)

13/16

Standard Flange Size

NW25

Intake Thread Size

1-20

Exhaust Thread Size

1-20

Electrical Requirements 1

115V/230V

Electrical Requirements 2

60Hz

Electrical Requirements 3

1 Phase

Replacement Parts

Shaft Seal: Lip Seal

1401D -01

Shaft Seal: Mechanical Seal

1401D

Air Filter Screen

41-0660

Intake Chamber Cover Gasket

41-0234

Oil Case Gasket

41-0403

Drain Plug

61-2278

Oil Window

61-2229A

Large Vane

41-0959

Small Vane

41-1487

Large Vane Spring

41-1304

Small Vane Spring

41-1304

Large Vane Spring Holder

41-1685

Small Vane Spring Holder

41-1685

Shaft

41-2093

Upper Exhaust Valve

41-2153

Lower Exhaust Valve

41-2154

Pressure Release Valve

41-0992

Optional Exhaust Filter

1417P-10

Optional Exhaust Filter

Element

1417G

Pump Pulley

41-2074

Standard Belt

1405A

Standard Hose Barb Fitting

1393K

Standard Flange Adapter

Fitting

1393G

Repair Kits

Minor Repair Kit

1402K-05

Major Repair Kit

1402K-06

Base and Belt Guard Kit

1371A-01

Содержание DUOSEAL 1402B-01

Страница 14: ...14 Section 6 DIMENSIONAL DRAWING...