20

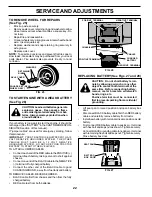

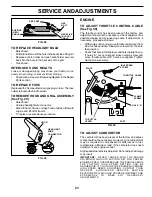

TO ADJUST BRAKE (See Fig. 22)

Your tractor is equipped with an adjustable brake system

which is mounted on the side of the transaxle.

If tractor requires more than six (6) feet stopping distance at

high speed in highest gear on a level dry concrete or paved

surface, then brake must be adjusted.

•

Depress clutch/brake pedal and engage parking brake.

•

Measure distance between brake operating arm and nut

“A” on brake rod.

FIG. 21

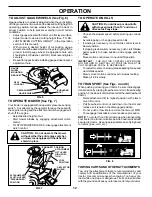

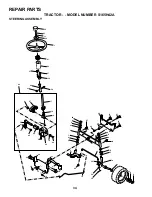

TO REPLACE MOWER BLADE DRIVE BELT

(See Fig. 21)

The mower blade drive belt may be replaced without tools.

Park the tractor on level surface. Engage parking brake.

BELT REMOVAL -

•

Remove mower from tractor (See “TO REMOVE

MOWER” in this section of this manual).

•

Work belt off both mandrel pulleys and idler pulleys.

•

Pull belt away from mower.

BELT INSTALLATION -

•

Install new belt in reverse order of removal.

•

Make sure belt is in all pulley grooves and inside all belt

guides.

•

Install mower in reverse order of removal instructions.

SERVICE AND ADJUSTMENTS

NUT "E"

"D"

"D"

MANDREL

FIG. 19

NUT "F"

FRONT LINKS

FIG. 20

BOTH FRONT LINKS MUST BE EQUAL IN LENGTH

SUSPENSION ARM

LIFT LINK ADJUSTMENT NUT

FIG. 18

TRUNNION

•

To raise one side of mower, tighten lift link adjustment

nut on that side.

•

To lower one side of mower, loosen lift link adjustment

nut on that side.

NOTE: Three full turns of adjustment nut will change mower

height about 1/8".

•

Recheck measurements after adjusting.

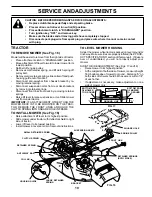

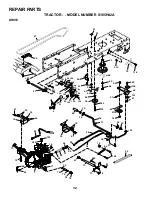

FRONT-TO-BACK ADJUSTMENT (See Figs. 19 and 20)

IMPORTANT: DECK MUST BE LEVEL SIDE-TO-SIDE. IF

THE FOLLOWING FRONT-TO-BACK ADJUSTMENT IS

NECESSARY, BE SURE TO ADJUST BOTH FRONT LINKS

EQUALLY SO MOWER WILL STAY LEVEL SIDE-TO-

SIDE.

To obtain the best cutting results, the mower housing should

be adjusted so that the front is approximately 1/8" to 1/2"

lower than the rear when the mower is in its highest position.

Check adjustment on right side of tractor. Measure distance

“D” directly in front and behind the mandrel at bottom edge

of mower housing as shown.

•

Before making any necessary adjustments, check that

both front links are equal in length. Both links should be

approximately 10-3/8".

•

If links are not equal in length, adjust one link to same

length as other link.

•

To lower front of mower loosen nut “E” on both front links

an equal number of turns.

•

When distance “D” is 1/8" to 1/2" lower at front than rear,

tighten nuts “F” against trunnion on both front links.

•

To raise front of mower, loosen nut “F” from trunnion on

both front links. Tighten nut “E” on both front links an

equal number of turns.

•

When distance “D” is 1/8" to 1/2" lower at front than rear,

tighten nut “F” against trunnion on both front links.

•

Recheck side-to-side adjustment.

IDLER PULLEYS

MANDREL PULLEY

MANDREL

PULLEY

Содержание S165H42A

Страница 44: ...44 SERVICE NOTES...

Страница 48: ......