17

Working with the machine

Starting the engine

WARNING

Danger of suffocation from engine exhausts when starting

the engine in closed rooms or poorly ventilated work areas.

Start the engine only in well-ventilated environments.

See section “Safety” for operating the machine in trenches.

ATTENTION

Risk of engine damage caused by insufficient lubrication

after horizontal transport.

Following horizontal transport, set up the machine vertically

and wait several minutes until the engine oil has collected

in the lower area of the crankcase.

Start the engine as described.

ATTENTION

Risk of engine damage. The use of starter spray may lead to

overheating in the combustion chamber.

Do not use any starter spray.

Bring the gas lever into full-throttle position (max.).

A valve opens the fuel line automatically.

Slide the choke lever in arrow direction (all the way to the right).

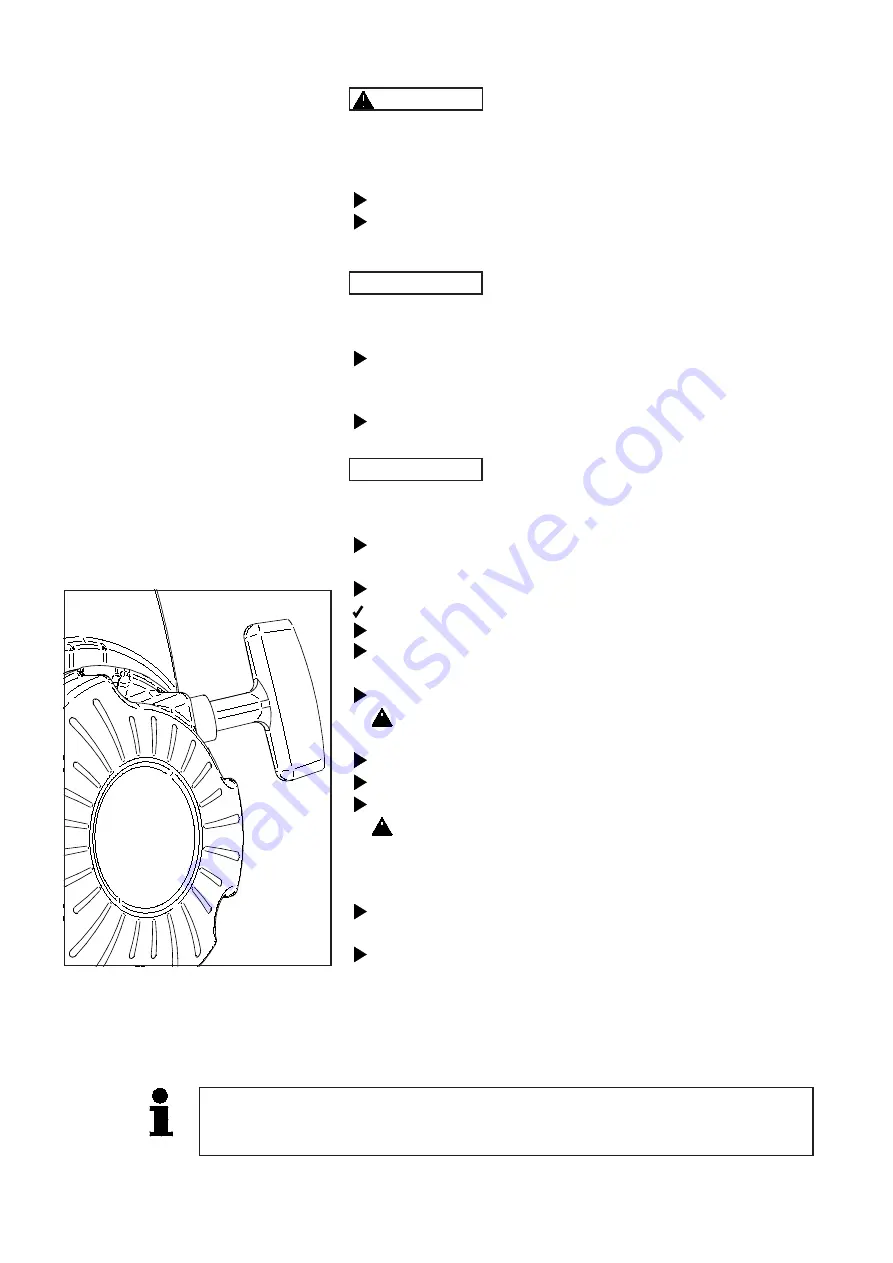

Slowly pull the handle of the reversing starter until resistance

(the compression of the engine) is noticeable.

Allow the handle to glide back into the initial position.

CAUTION! The tamper may tip over when the reversing

starter is pulled. There is a crushing hazard.

Hold on firmly to the tamper while starting it.

Pull the handle through quickly, forcefully and completely.

Repeat the process if the engine does not start.

CAUTION! As soon as it starts running, the engine will

increase the speed. There is a risk of injury as the tamper

is started at full throttle and may perform unexpected

movements.

Set the gas lever to idle speed immediately after the engine

has started to run.

Allow the engine to warm up for a few minutes before

sliding the choke lever all the way to the left.

The engine is equipped with an oil monitoring system. Abort the start-up

procedure if the red LED on the protective frame comes on during the

start-up procedure. Check the oil and top off if necessary.