135

November 1992

Part No. 917543 Rev. A

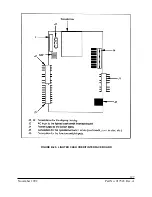

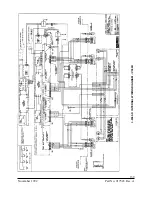

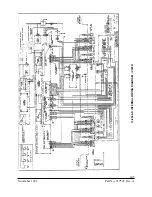

FIGURE C-1. DUPLEX II CONNECTOR PINOUTS FOR NON-BLENDERS

Pin 1-Relay Select Nozzle X

Pin 2-Fast Valve Nozzle X

Pin 3-Slow Valve Nozzle X

Pin 4-Relay Select Nozzle Y

Pin 6-Fast Valve Nozzle Y

Pin 7-Pulser Select Nozzle X

Pin 9-Slow Valve Nozzle Y

Pin 10-Pulser Select Nozzle Y

Pin 12-Fast Valve Nozzle Z

Pin 13-Pulser Select Nozzle Z

Pin 14-Relay Select Nozzle Z

Pin 15-Slow Valve Nozzle Z

J1-Side 1 Connections

J2-Side 2 Connections

J10-Side 2

Connections

J1

1

SOLENOID DRIVE BOARD

COMPUTER

JDB-FH-223-A

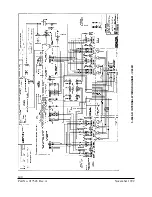

J9-Side 1

Connections

Pin 1-Nozzle Switch Nozzle X

Pin 2-Nozzle Common

Pin 3-Pulse "B"

Pin 4-LED "B"

Pin 6-Pulse "A"

Pin 7-LED "A"

Pin 8-Nozzle Switch Nozzle Y

Pin 9-Nozzle Switch Nozzle Z

Pin 1-Side 1 Nozzle Switch Nozzle AA

Pin 3-Side 2 Nozzle Switch Nozzle AA

Pin 6-Nozzle Common

Pin 1-Relay Select Nozzle X

Pin 2-Fast Valve Nozzle X

Pin 3-Slow Valve Nozzle X

Pin 4-Relay Select Nozzle Y

Pin 6-Fast Valve Nozzle Y

Pin 7-Pulser Select Nozzle X

Pin 9-Slow Valve Nozzle Y

Pin 10-Pulser Select Nozzle Y

Pin 12-Fast Valve Nozzle Z

Pin 13-Pulser Select Nozzle Z

Pin 14-Relay Select Nozzle Z

Pin 15-Slow Valve Nozzle Z

J3-Side 1

Connections

Pin 1-Fast Valve Nozzle AA

Pin 2-Slow Valve Nozzle AA

Pin 3-Relay Select Nozzle AA

Pin 4-Pulser Select Nozzle AA

J4-Side 2

Connections

Pin 1-Fast Valve Nozzle AA

Pin 2-Slow Valve Nozzle AA

Pin 3-Relay Select Nozzle AA

Pin 4-Pulser Select Nozzle AA

Pin 1-Nozzle Switch Nozzle X

Pin 2-Nozzle Common

Pin 3-Pulse "B"

Pin 4-LED "B"

Pin 6-Pulse "A"

Pin 7-LED "A"

Pin 8-Nozzle Switch Nozzle Y

Pin 9-Nozzle Switch Nozzle Z

NOTE: Pin connections which are not needed in a particular model of dispenser (for instance, the nozzle

Z switch in a V387 dispenser) will have no wire in that location.

Содержание Vista Series

Страница 1: ...SERVICE Vista Blending and Non blending Suction Pumps and Remote Dispensers...

Страница 4: ...Part No 917543 Rev A November 1992...

Страница 12: ...x Part No 917543 Rev A November 1992...

Страница 34: ...22 Part No 917543 Rev A November 1992 FIGURE 4 1 NOZZLE BOOT ASSEMBLY WITH MICRO SWITCH...

Страница 35: ...23 November 1992 Part No 917543 Rev A FIGURE 4 2 NOZZLE BOOT ASSEMBLY WITH TILT SWITCH...

Страница 36: ...24 Part No 917543 Rev A November 1992...

Страница 53: ...41 November 1992 Part No 917543 Rev A FIGURE 5 7 METER CUTAWAY...

Страница 54: ...42 Part No 917543 Rev A November 1992 FIGURE 5 8 METER ADJUSTMENT...

Страница 58: ...46 Part No 917543 Rev A November 1992...

Страница 69: ...57 November 1992 Part No 917543 Rev A FIGURE 7 1 REPLACING THE DUPLEX II COMPUTER...

Страница 71: ...59 November 1992 Part No 917543 Rev A FIGURE 7 2 REPLACING THE INTRINSIC SAFE BARRIER BOARD...

Страница 72: ...60 Part No 917543 Rev A November 1992 FIGURE 7 3 REPLACING THE INTEGRATED DISPLAY BOARD...

Страница 74: ...62 Part No 917543 Rev A November 1992 FIGURE 7 4 REPLACING THE LIGHTED CASH CREDIT INTERFACE BOARD...

Страница 75: ...63 November 1992 Part No 917543 Rev A FIGURE 7 5 REPLACING THE SOLENOID DRIVE BOARD...

Страница 82: ...70 Part No 917543 Rev A November 1992...

Страница 84: ...72 Part No 917543 Rev A November 1992...

Страница 105: ...93 November 1992 Part No 917543 Rev A APPENDIX B ELECTRONIC ELECTRICAL COMPONENT TROUBLESHOOTING...

Страница 106: ...94 Part No 917543 Rev A November 1992...

Страница 110: ...98 Part No 917543 Rev A November 1992 FIGURE B 4 THE DEM IN THE SERVICE POSITION...

Страница 112: ...100 Part No 917543 Rev A November 1992 FIGURE B 6 DUPLEX II COMPUTERS J3 CONNECTOR PINOUT...

Страница 113: ...101 November 1992 Part No 917543 Rev A FIGURE B 7 DUPLEX II COMPUTERS J9 AND J10 CONNECTOR PINOUT...

Страница 114: ...102 Part No 917543 Rev A November 1992 FIGURE B 8 DUPLEX II COMPUTERS J11 CONNECTOR PINOUT...

Страница 115: ...103 November 1992 Part No 917543 Rev A FIGURE B 9 DUPLEX II COMPUTERS J6 CONNECTOR PINOUT...

Страница 116: ...104 Part No 917543 Rev A November 1992 FIGURE B 10 DUPLEX II COMUTERS J1 CONNECTOR PINOUT...

Страница 125: ...113 November 1992 Part No 917543 Rev A FIGURE B 18B 4 PRODUCT SOLENOID DRIVE BOARD...

Страница 126: ...114 Part No 917543 Rev A November 1992 FIGURE B 18C BLENDER SOLENOID DRIVE BOARD...

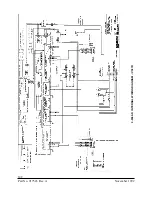

Страница 127: ...115 November 1992 Part No 917543 Rev A FIGURE B 19 SOLENOID DRIVE BOARD CONNECTOR J1 AND J2 PIN DEFINITIONS...

Страница 128: ...116 Part No 917543 Rev A November 1992 FIGURE B 20A 4 PRODUCT SOLENOID DRIVE BOARD J3 AND J4 CONNECTOR PIN DEFINITIONS...

Страница 129: ...117 November 1992 Part No 917543 Rev A FIGURE B 20B BLENDER SOLENOID DRIVE BOARD J7 AND J8 CONNECTOR PIN DEFINITIONS...

Страница 133: ...121 November 1992 Part No 917543 Rev A FIGURE B 24 MANUALLY TURNING THE PHOTOCOUPLER...

Страница 135: ...123 November 1992 Part No 917543 Rev A FIGURE B 26 INTRINSIC SAFE BARRIER J2 AND J5 CONNECTOR PINOUTS...

Страница 136: ...124 Part No 917543 Rev A November 1992 FIGURE B 27 INTRINSIC SAFE BARRIER J3 AND J6 CONNECTOR PINOUT...

Страница 139: ...127 November 1992 Part No 917543 Rev A FIGURE B 29 LIGHTED CASH CREDIT INTERFACE BOARD...

Страница 140: ...128 Part No 917543 Rev A November 1992 FIGURE B 30 LIGHTED CASH CREDIT INTERFACE BOARD J3 CONNECTOR...

Страница 141: ...129 November 1992 Part No 917543 Rev A FIGURE B 31 LIGHTED CASH CREDIT INTERFACE BOARD J4 CONNECTOR...

Страница 142: ...130 Part No 917543 Rev A November 1992 FIGURE B 32 LIGHTED CASH CREDIT INTERFACE BOARD J6 CONNECTOR...

Страница 144: ...132 Part No 917543 Rev A November 1992...

Страница 145: ...133 November 1992 Part No 917543 Rev A APPENDIX C DISPENSER INTERNAL WIRING DIAGRAMS...

Страница 146: ...134 Part No 917543 Rev A November 1992...

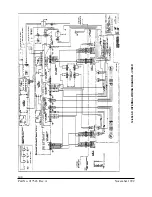

Страница 150: ...138 Part No 917543 Rev A November 1992 1 6560 D INTERNAL WIRING DIAGRAM V390D...

Страница 151: ...139 November 1992 Part No 917543 Rev A 3 6560 D INTERNAL WIRING DIAGRAM V399D...

Страница 152: ...140 Part No 917543 Rev A November 1992 5 6560 D INTERNAL WIRING DIAGRAM V490D...

Страница 153: ...141 November 1992 Part No 917543 Rev A 7 6560 D INTERNAL WIRING DIAGRAM V590D...

Страница 154: ...142 Part No 917543 Rev A November 1992 9 6560 D INTERNAL WIRING DIAGRAM V387D...

Страница 155: ...143 November 1992 Part No 917543 Rev A 11 6560 D INTERNAL WIRING DIAGRAM V390P...

Страница 156: ...144 Part No 917543 Rev A November 1992 12 6560 D INTERNAL WIRING DIAGRAM V585D...

Страница 157: ...145 November 1992 Part No 917543 Rev A 13 6560 D INTERNAL WIRING DIAGRAM V395D...

Страница 158: ...146 Part No 917543 Rev A November 1992 19 6560 D INTERNAL WIRING DIAGRAM V390D J SINGLE HOSE MGD...

Страница 159: ...147 November 1992 Part No 917543 Rev A APPENDIX D GILBARCO PULSER INTERFACE PCB TROUBLESHOOTING...

Страница 160: ...148 Part No 917543 Rev A November 1992...

Страница 162: ...150 Part No 917543 Rev A November 1992 FLOWCHART D1 PULSER FAILURE ERROR CODE XX 05 2...