5

www.waynepumps.com

CWS Series

INSTALLATION (CONTINUED)

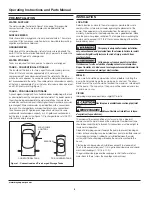

PRESSURE SWITCH

The pressure switch provides for automatic operation. The pump starts

when pressure drops to a cut-in setting. The pump stops when pressure

reaches a cut-out setting. The pressure switch preset and is

NOT

adjustable.

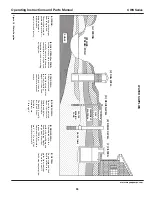

PIPE SIZES

Long horizontal pipe runs and an abundance of fittings and couplers

decrease water pressure due to friction loss. See Chart 1, on page 5, to

determine the proper pipe size.

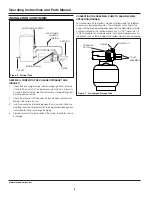

SHALLOW WELL INSTALLATION

A shallow well jet assembly can be used with the deep well pump when

the pump is located a maximum of 25 ft vertically above the water level

(see converting to shallow well pump on page 7). Shallow well installations

have only one pipe between the pump and water supply (Figure 2).

DRILLED WELL (FIGURE 16, PAGE 13)

1. Install a foot valve on the first section of pipe (Figure 2, Illustration A).

2. Lower the pipe into the well.

3. Add pipe until the foot valve is 5 feet below the lowest anticipated

water level.

The foot valve must be at least 18 in. from the

bottom of the well or sand or sediment could be drawn into the system.

MISE EN GARDE

Le clapet de pied doit au moins être à 45,7

cm (18 po) du fond du puits, sinon du sable ou des sédiments pourraient

être aspirés dans le système.

4. After proper depth is reached, install a well seal or pitless adapter to

support pipe and prevent surface. water and other contaminants

from entering well.

5. Slope the horizontal pipe upward toward the pump to eliminate

trapping air. Sloping the pipe will also aid in priming the pump.

DRIVEN WELL (FIGURE 16, PAGE 13)

•

Drive the point several feet below the water table.

NOTE:

A packer type foot valve can be installed in the well (Figure 2,

Illustration B). This type of foot valve allows the piping to be filled with

water when priming and makes the inlet pipe much easier to test for

leaks. Follow the manufacturer’s instructions when installing the packer

type foot valve.

As an alternative, an in-line check valve can be used with a driven well

(Figure 2, Illustration C). The pipe between the check valve and the water

level will always be under a vacuum.

Leaking joints or couplings will allow air to leak into the pipe and cause

abnormal pump operation. Make sure to use pipe joint compound on all

male pipe threads.

DUG WELL, CISTERN, LAKE AND SPRING INSTALLATION

(FIGURE 16, PAGE 13)

•

Install a foot valve on inlet pipe and lower into water.

The foot valve must be at least 18 in. from the

bottom of the well or sand or sediment could be drawn into the system.

MISE EN GARDE

Le clapet de pied doit au moins être à 45,7

cm (18 po) du fond du puits, sinon du sable ou des sédiments pourraient

être aspirés dans le système.

NOTE:

When a lake is used as a water supply, make sure the inlet pipe

is deep enough to be submerged at all times.

Slope the horizontal piping upward toward the pump to prevent trapping

air. The pipe must be removed during winter months or protected against

freezing.

Protect the pipe from damage from swimmers and boats.

Install a screen around the inlet pipe to prevent

the entrapment of swimmers, wildlife and debris.

Installer un écran autour du tuyau d’entrée pour

éviter de piéger des nageurs, des animaux et des débris.