HTC4000 TEMPERA

TURE CONTROLLER

www.teamwavelength.com

© 2012

HTC4000-62400-B

PAGE 8

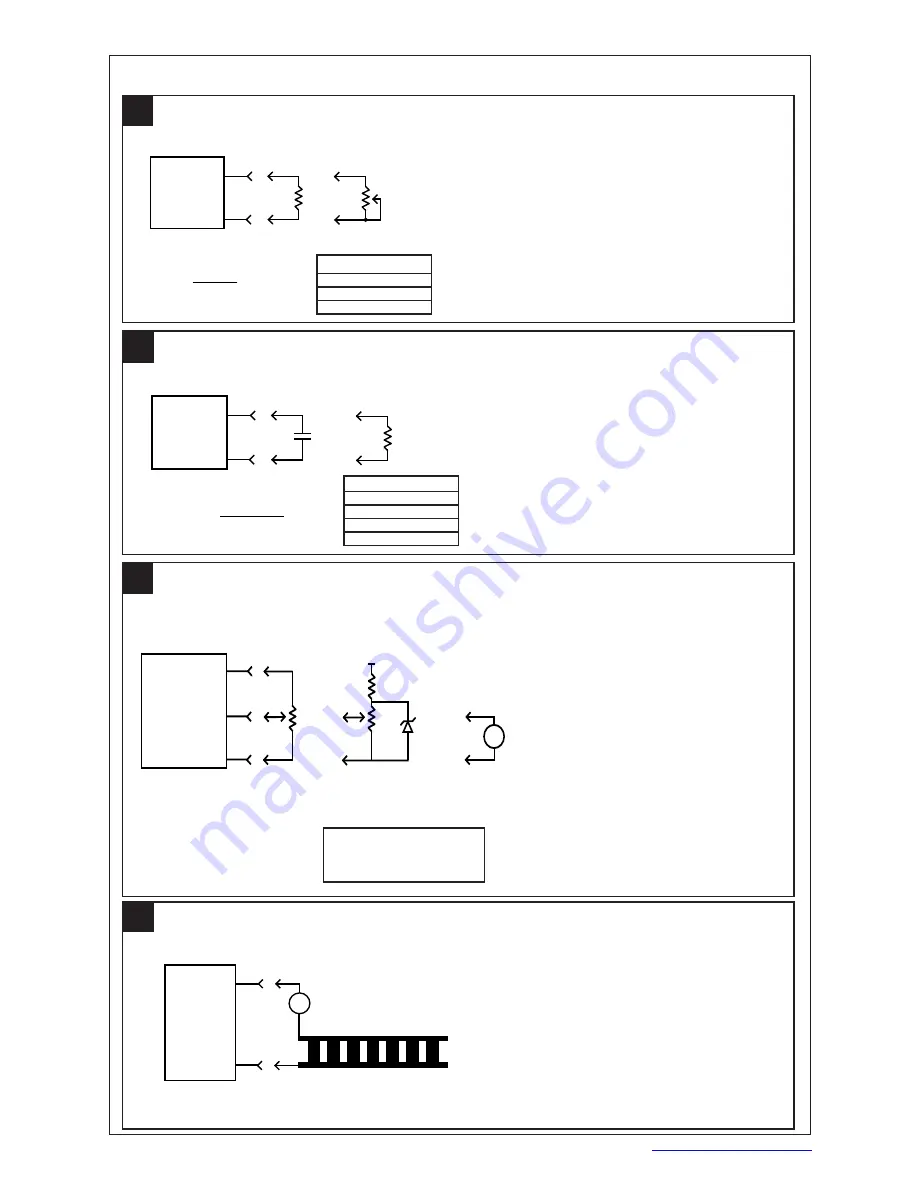

The controller adjusts the temperature

of the load until the voltage across the

temperature sensor equals the Setpoint

Input voltage (pins 8 & 15). To adjust the

temperature setpoint, first determine the

voltage across the sensor at the target

temperature; apply that same voltage

across pins 8 and 15 of the controller.

The diagrams to the left show three

possible configurations for setpoint

voltage input.

C

INT

=

1 M

Ω

T

INT

17

18

Fixed,

Metal Film

OR

R +

R -

Adjustable

(500 k

Ω

typical)

PROP

PROP

Use a trimpot no more than twice the

calculated value of R

PROP

for best resolution.

R

PROP

sets the gain of the system from 1

to 100. A higher proportional gain can

help minimize the time to settling but may

destabilize loads with long intrinsic lag times.

Too low a gain may result in oscillations

about setpoint. For most applications, a gain

of 33 works (R

PROP

= 10 kΩ). Change the

proportional gain while the output is OFF.

Proportional Gain - Pins 17 & 18

C

int

sets the integral time constant of the

system from 0 to 10 seconds. Use a capacitor

with Dissipation Factor less than 1% for best

performance. These typically include metallized

film polyester, polypropylene & some ceramic

capacitors. Capacitors with Dissipation Factors

>1% (typically electrolytic, tantalum, and ceramic)

will cause drift in the Integrator circuit. To disable

the integrator, use a 1 M

Ω

resistor across pins

19 & 20.

R

PROP

=

500 k

Ω

GAIN - 5 k

Ω

19

20

C +

C -

INT

INT

C

INT

Fixed,

Metal Film

OR

1 M

Ω

C

INT

1 M

Ω

1

µ

F

5

µ

F

10

µ

F

T

INT

0 (OFF)

1 second

5 seconds

10 seconds

4

8

3.675 V Ref Out

Setpoint Input

(V+ Maximum)

Common 5

R

1

R

1

= 10 k to

100 k

Ω

Use Ref

Voltage

Provided

R

1

Use V+

for higher

sense voltage

1 k

Ω

V+

OR

Apply

Remote

Voltage

+

-

V

REF

Select V

REF

to cover

your temperature range

OR

11

12

TEC +

TEC -

Optional Ammeter

to monitor

TE Current

A

Connect the TE module and an ammeter

if you want to monitor TE current. Current

flows from positive to negative when the

HTC is cooling with an NTC temperature

sensor. When using an LM335, AD590,

RTD, or other PTC sensor, reverse the

polarity of the leads (i.e. connect the

positive lead of the TE module to TEC-

and the negative lead of the TE module

to TEC+).

Integrator Time Constant - Pins 19 & 20

Temperature Setpoint - Pins 8 & 5 (Pin 4 optional)

TE Module & Output Current Measurement - Pins 11 & 12

Monitor setpoint with a DVM

at pins 7 & 5, or actual sensor

voltage across pins 6 & 5.

6

5

7

8

R

PROP

495 k

Ω

5 k

Ω

0

Ω

GAIN

1

50

100

OPERATION WITH THERMOELECTRICS, continued

Example:

Desired Temperature:

25

°

C

Sensor:

10 k

Ω

thermistor

Resistance at 25

°

C:

10 k

Ω

Bias Current:

100

µ

A

V

SET

= 10 k

Ω

* 100

µ

A = 1 V