©

“WATEX” Ltd., Reg. Nr. 40003712811, Ganibu dambis 27 k-5, Riga, LV-1005; Contact information: tel. +371 67381989, e-mail:

[email protected], www.watex.eu

8

3.

INSTALLATION

3.1. General conditions

Pressure tanks must be on a flat, level surface; It is recommended to install the equipment in a

soundproofed technical room, as the water flow into the sewer during regenerations may be heard

(default at night). The control valve and connection fittings are not designed to support the weight of

the water supply system. All sanitary works must be performed in accordance with Latvian

legislation or the countries legislation where the equipment is installed. The equipment must be

provided with continuous water supply and a pressure in the range of 2.0 to 3.5 bar. Ensure that the

temperature does not 30oC. The room temperature must not be lower than +5 oC and

higher than 45 oC. It is recommended to install a mechanical filter before the equipment. Do not use

Vaseline, oil, hydrocarbon grease, or aerosol silicone on the control valve connections. Silicone

grease can be used on black o-ring seals, but it is not required.

Nuts and fittings are designed to be unscrewed or tightened by hand or with a special plastic key.

Pliers can be used if it is necessary to loosen tightened nuts or fittings. Handle with care, do not

damage plastic parts. Do not use a wheel wrench to tighten or unscrew nuts or fittings. Do not insert

a screwdriver into the holes in the sleeves and do not strike with a hammer! Teflon tape is not

required for sewer and reagent addition fittings. Position the water filter so that the distance between

the drain and the filter is as small as possible. Perform general preventive maintenance of the

equipment at least once a year.

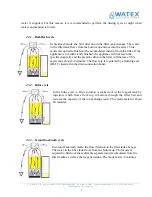

3.2. Connecting to water supply

There are incoming and outgoing water connection ports at the

rear of the CLACK control valve. Inlet and outlet are indicated

by arrows for each connection. If you look at the equipment

from the front, there is an inlet on the right and an outlet on the

left. The size of the external thread of the water supply

connection to the unit is 1 '' (inch) for both inlet and outlet. The

plastic threaded fitting is screw type and can rotate freely on

the ring while maintaining tightness. Therefore, it is not

necessary to tighten the screw on the control unit housing very

strongly (enough force by hand). Teflon tape must be used on

the plastic threads. There is no significant difference in the material of the pipes that connect to the

equipment. The main thing is that the appliance does not have to carry the weight of the water

supply system. The device can be connected with fusible, glued, screwed plastic pipes. It can also be

made with flexible metal pipes or brass solder.

Note: Soldered pipes must be soldered before attaching them to the plastic fittings on the control

valve. Failure to do so may result in internal damage to the plastic fittings and failure to provide a

seal. Solder fittings must first be cooled. Avoid getting solder grease on any part of the connection

fitting.