©

“WATEX” Ltd., Reg. Nr. 40003712811, Ganibu dambis 27 k-5, Riga, LV-1005; Contact information: tel. +371 67381989, e-mail:

[email protected], www.watex.eu

5

water consumption. The equipment control valve has a daily or weekly calendar (Monday to

Sunday) and you can program which of these days the machine should rinse.

2.1.2. Brine tank

The brine tank is designed to store Sodium Chloride NaCl (Salt Tablets). Inside there are several

components: a float inserted in a cylindrical tube and an overflow outlet. The float regulates the

amount of water in the reagent tank to be used during the regeneration cycle. The float level can be

adjusted, but it is not necessary to do so in normal operation. Normally the water level should be

about 1/3 of the height of the salt container. This is sufficient to dissolve part of the NaCl for the

regeneration cycle.

2.2.System operation

The operation of the equipment has two main basic

cycles - the service and regeneration (rinsing) cycle.

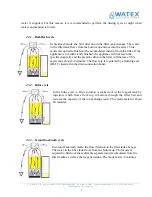

Service cycle

In the service cycle, water is fed to the control valve via

the raw water inlet, then flows into the filter tank from

above and flows through the filter material to purify the

water, and then flows back through the collector pipe to

the control valve and then to the consumers. During this

time, the reagent tank should contain water

approximately 1/3 of the height of the brine tank to

dissolve the Salt (NaCl) used to recover the filter media.

The duration of the service cycle depends on the quality

of the incoming water, the amount of filter material and

the amount of water consumed. If one of the consumers

uses water during the service cycle, "SOFTENING"

appears on the display of the CMS series models. The

WATEX CMS series has a built-in meter that counts the

amount of water consumed. With the help of the

electronic display, it is possible to set the volume of

water (m3) after which has been consumed the control valve starts regenerations. As soon as the

meter has counted the specified volume of water, the equipment will start at the regeneration the

same night. At 2.00 o clock (factory setting) the regeneration cycle is started. The start of the

regeneration cycle can be changed via the electronic display.

2.3.

Regeneration cycle schemes

The equipment requires a rinsing cycle to remove accumulated material from the filter and restore

the capacity of the filter media. The capacity of the filter material is expressed in m3, so the meter

built into the WATEX CMS model counts the amount of water consumed and after a certain

consumption of m3 the unit switches to the rinsing cycle. The rinsing cycle lasts approximately 1.5

hours and consists of several modes. The machine has 4 main modes: countercurrent rinsing, reagent

suction, to the consumers flow rinsing and filling the reagent tank. The order of the modes can be

changed on the control valve, but we recommend using the order of the modes already set at the

factory. To ensure a continuous supply of water to the consumers during the rinsing cycle, untreated