7

* For more detailed tech support notes & troubleshooting go to www.watergeneral.com

NOTE: Turn off the system before servicing.

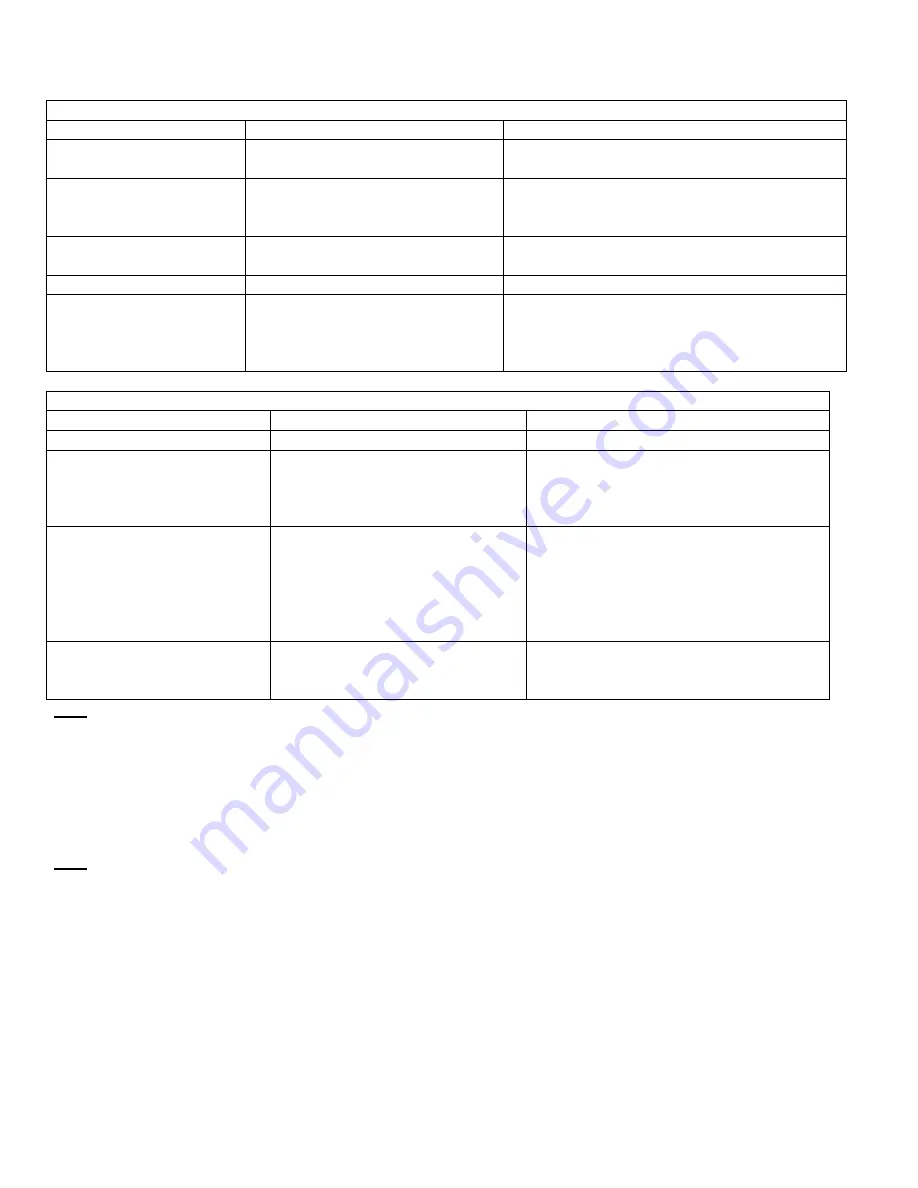

Installation Troubleshooting

PROBLEM

POSSIBLE CAUSE

SOLUTION

No or low water production 1. Feed water valve is not turn on

2. Tubing is kinked

1. Turn on feed water valve

2. Straighten the tubing

Leak at filter housing

1. Housing is not tighten

2. Damaged or misaligned O-ring

3. Housing has cracks

1. Use filter housing wrench to tighten housing

2. realign or replace O-ring

3. Replace housing

Leak at fitting thread

1. Not properly tighten

2. Fitting has cracks

1. Use Teflon tape, re-tighten

2. Replaced it

Milky/Cloudy water

1. Air in system/filters

1. This is normal, continue use it for 2 weeks

Noise from drain

Saddle valve mounted too high

1. Lower the saddle valve

When system is making water, waste water to

drain is normal, when storage tank is full, drain

should stop

Troubleshooting

PROBLEM

POSSIBLE CAUSE

SOLUTION

Vibrating noise or very loud

high pitch noise

1. From the auto shut-off valve

2. auto-shut-off valve is hitting

against the steel plate

1. If the noise is unbearable, shut-off valve

should be replaced.

2. Use bubble wrap or paper to wrap

around the valve so it doesn’t hit the plate

Drain water never shut off

1. Auto shut-off valve is worn out

or becoming ineffective

2. Water supply pressure is 50 psi

or below

3. Cold water temperature

4. Filters are clogged up

1. Replace auto shut-off valve

2. Booster pump is needed for input water

pressure less than 50

3. the system makes water slower at cold

temperature

4. Replace filters

Low water production

1. Clogged filters

2. Kinked tubing

3. Clog flow restrictor

1. Replace filters

2. Straighten the tubing

3. Replace flow restrictor

Note: Clogged filters: How do you know if the filters are clogged up? For the pre-filters, sediment filters and carbon

filters; check the pressure difference before and after the filters. If there is significant difference in pressure that means

the filter is clogged. Turn OFF tank valve and cold water main valve then open the RO faucet to depressurize the system,

then disconnect the tubing after the bottom three pre-filters, then turn ON the cold water main valve. If you get very

strong water pressure, (as strong as water going into the system) then the bottom 3 pre-filters are not clogged. If the water

pressure is much smaller, unlike a burst of water pressure, then the bottom 3 pre-filters need to be replaced. Note:

Checking a clogged membrane uses different method. Use a water quality meter TDS meter to check the condition and

performance of the RO membrane (4

th

stage filter)

Note: Clogged flow restrictor: When you disconnect the black tubing going into the saddle valve, and the RO system is

in the processing of making water (by turning on the RO faucet), there should be a small steady flow of drain water. If

you do not get any drain water, the flow restrictor may be clogged, then you need to replace a new flow restrictor ASAP,

and discontinue using the system.

NOTE: If after few days of running the system, the problem comes back, then you may need to replace a new tank.