4

TRUCLIMATE 700 90-140 TON INSTALLATION MANUAL

Safety Considerations

This appliance is not intended for use by persons

(including children) with reduced physical, sensory,

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervi-

sion or instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance.

Maximum altitude for this equipment shall not

exceed 2000 m.

For installation only in locations not accessible to

the general public.

Installing and servicing air conditioning and

heating equipment can be hazardous due to system

pressure and electrical components. Only trained and

qualified service personnel should install, repair or service

heating and air conditioning equipment. When working

on heating and air conditioning equipment, observe

precautions in the literature, tags and labels attached to the

unit and other safety precautions that may apply.

Follow all safety codes. Wear safety glasses and work

gloves. Use quenching cloth for brazing operations. Have

fire extinguisher available for all brazing operations.

NOTE:

Before installing, check voltage of unit(s) to ensure

proper voltage.

WARNING: Before performing service or

maintenance operations on the system, turn off

main power switches to the unit. Electrical shock

could cause serious personal injury.

Application

Units are not intended for heating domestic (potable water)

by direct coupling. If used for this type of application, a

secondary heat exchanger must be used.

Moving and Storage

Move units in the normal “Up” orientation as indicated by

the labels on the unit packaging. When the equipment

is received, all items should be carefully checked against

the bill of lading to ensure that all crates and cartons

have been received in good condition. Examine units for

shipping damage, removing unit packaging if necessary

to properly inspect unit. Units in question should also

be internally inspected. If any damage is observed, the

carrier should make the proper notation on delivery receipt

General Installation Information

acknowledging the damage. Units are to be stored in a

location that provides adequate protection from dirt, debris

and moisture.

Units are setup to be side picked using a fork lift. Some

units include pick bars allowing for picking from the end

with required fork lengths. Note unit labels and markings

for safe picking points. Do not pick the unit up from points

not specified and keep the unit level during transport and

handling. Using improper equipment handling methods can

result in damage and/or void the warranty.

WARNING: To avoid equipment damage, do not

leave the system filled in a building without heat

during cold weather, unless adequate freeze

protection levels of antifreeze are used. Heat

exchangers do not fully drain and will freeze

unless protected, causing permanent damage.

Unit Location

Provide sufficient room to make water and electrical

connections. If the unit is located in a confined space,

provisions must be made for unit servicing. Locate the

unit in an indoor area that allows easy removal of the

access panels and has enough space for service personnel

to perform maintenance or repair. These units are not

approved for outdoor installation and, therefore, must be

installed inside the structure being conditioned. Do not

locate units in areas subject to freezing conditions.

WARNING: Do not store or install units in

corrosive environments or in locations subject

to temperature or humidity extremes. Corrosive

conditions and high temperature or humidity can

significantly reduce performance, reliability, and

service life.

WARNING: To avoid equipment damage and

possible voiding of warranty, be sure that properly

sized strainers are installed upstream of both

brazed plate heat exchangers to protect them

against particles in the fluid.

Содержание TruClimate 700

Страница 2: ......

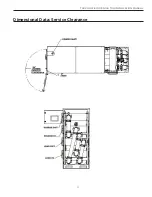

Страница 10: ...10 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Dimensional Data...

Страница 11: ...11 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Dimensional Data Service Clearance...

Страница 12: ...12 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Dimensional Data Center of Gravity...

Страница 13: ...13 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Dimensional Data Rigging Data...

Страница 25: ...25 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Wiring Schematic next page...

Страница 36: ...36 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Evaporator Pressure Drop...

Страница 37: ...37 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Condenser Pressure Drop...

Страница 39: ...39 TRUCLIMATE 700 90 140 TON INSTALLATION MANUAL Screw Refrigeration Cycle Analysis...