21

warmhaus.com

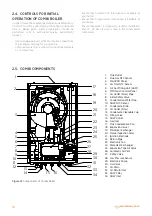

Figure 31

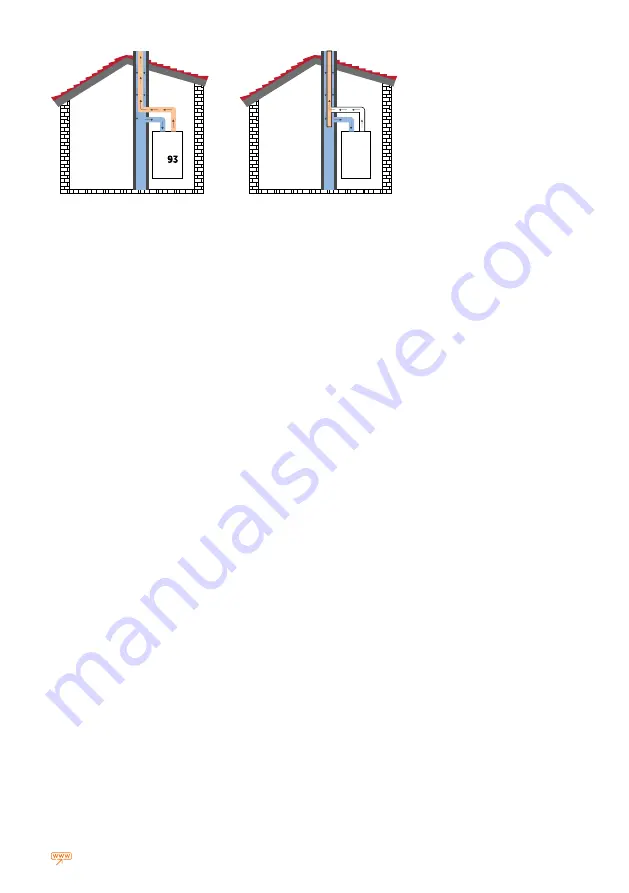

Exhaust gas discharge through the building chimney and fresh intake from the building chimney with split

flue sets

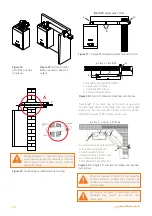

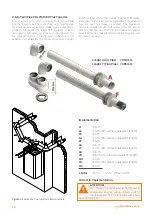

Attention:

The minimum usable

diameter must not be under 80 mm

or equivalent for the vertical duct

supplying the combustion air.

Attention:

a) nominal working combustion product temperature : > 70°C max

conditions

b) overheat combustion products temperature : 105° C

c) the minimum length of the specified connecting ducts; 1 mt / maximum

length of the specified connecting ducts; 10 mt

d) For size/shape of the end of the fitting please refer 2.2.14. Installation with

Vertical Flue Sets page 13, Fig.26.

e) Please re adjust TsP Paramater P22 = Flues gas pipe length ( value 1 = 1

meter ) according to actual flue lenght

f) Its MUST to use NON RETURN valve ON the flue gas system.

g) non-return valve function has to be checked annually by authorised

service.

Information for the design of the common duct system for a

type C(10) boiler

a) The boiler is designed to become connected to a common duct system

that is designed to operate where the static pressure in the common flue

duct might exceed the static pressure in the common air duct by 25 Pa

under the condition that n-1 boilers are running at maximum nominal heat

input (Qn,max) and 1 boiler at the minimum heat input allowed by the

controls

b) combustion product mass flow rate at maximum nominal heat input are

given technical table.

c) combustion product mass flow rate at minimum heat input allowed by the

controls are given technical table.

d) G20 : CO2 or O2 content of the combustion products at nominal operating

conditions 9 % ( +0,5/-0,5 )

G30 / G31 : CO2-content; 10.00 % ( tolerance : +%0,5 / -0,5 % )

e) minimum allowable pressure difference between combustion product

outlet and air inlet shall be declared as -200 Pa (including -100 Pa wind

pressure).

General for connection of a type C(10) boiler to a common duct

system

Characteristics and the applications of the common duct system to which

the boiler can be connected, with at least the following information:

a) the flue duct system shall be CE marked and comply with EN 15502

standart 12.2.1.4.111.2;

b) nominal combustion products temperature for dimensioning the common

duct system shall be declared as 25 °C;

c) the combustion product mass flow rate at maximum heat input shall be

specified for every connection point; the terminal of the common duct

shall be designed to induce a draft;

d) condensate flow into the boiler is allowed;

e) maximum allowable recirculation rate of 10 % under wind conditions;

f) the maximum allowable pressure difference between combustion

product inlet and air outlet of the common duct system shall not be

exceeded when n-1 boilers are running at maximum nominal heat input

(Qn,max) and 1 boiler at the minimum heat input allowed by the controls;

g) the common flue duct shall be appropriate for an overpressure of at least

200 Pa;

h) the duct system shall not include a draft diverter.

Warning:

the boiler if it is installed as a C (10) boiler and IF / when the

boiler is disconnected the air outlet and the combustion product inlet

openings shall be closed and checked on tightness.

C

C

10

Содержание MINERWA 25

Страница 1: ...MINERWA 25 CONDENSING COMBI BOILER INSTALLATION USER MANUAL...

Страница 2: ...2 warmhaus com MINERWA 25...

Страница 49: ...49 warmhaus com 3 10 ENERGY LABEL...

Страница 50: ...50 warmhaus com...