Please read this installation and

operating instructions carefully

before beginning installation and

operation.

1. Application

1.1 The TPK series is multi-stage centrifugal

pump designed for transferring liquid

used in machine tools.

1.2 The pump can not be used to transfer

explosive liquids, such as gasoline,

diesel oil and other similar liquids.

It is only suitable for water diluted,

low viscosity, uncorrosive cooling

or lubricant liquids.

2. Model Explanation

The pump models are coded based on the

number of pump stages. Standard stages

consist of both diffusers and impellers, and

null stages, for special installation

considerations, contain diffuser chamber only.

The pump model is shown on the pump

nameplate.

Example:

TPK 2T 3 - 3

Number of Impellers

Number of Diffuser

Standard Capacity(m /hr)

Model Code

3

3. Technical Data

Liquid Temperature: +0

ƨ

~ +90

ƨ

Ambient Temperature: Max. +50

ƨ

Enclosure Class: IP54

Discharge Pressure: Max. 10 kg/cm

2

4. Installation

The motor surface temperature is

extremely high. It must be mounted

in the save place to avoid accidental

touch.

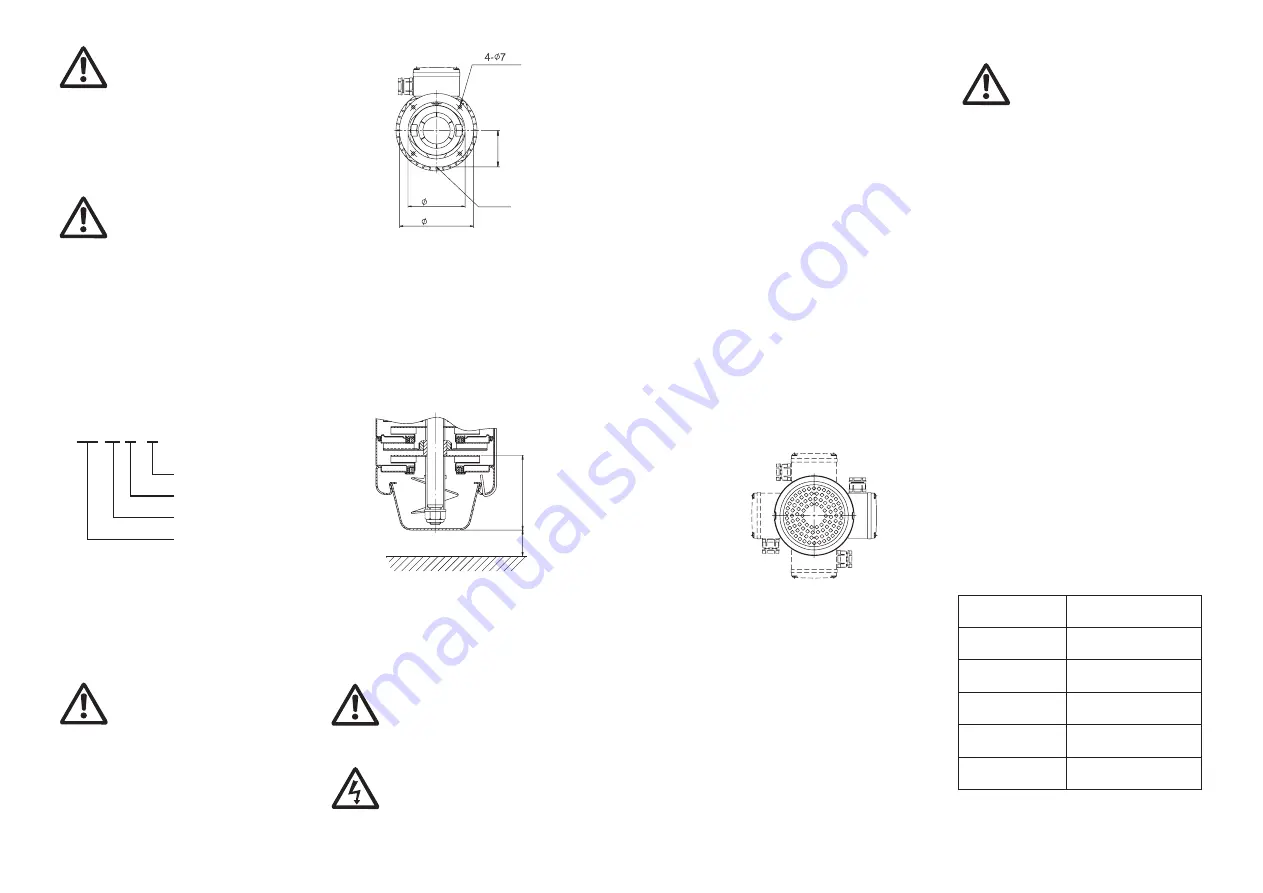

4.1 Mounting Position

The pump must be mounted vertically.

Installation is simply done by inserting the

pump into the hole on the tank top, and

fixed by four bolts in mounting flange.

Flange dimensions are shown in Fig 1.

64

100

130

PCD 115

Fig. 2

Fig. 1

PF 3/4"

Outlet

4.2 Submerged Depth

To avoid dry running and damage the

pump during operating, the minimum

pump submerged depth is 60mm, as

shown in Fig. 2. In addition, a minimum

25mm gap between pump suction inlet

and tank bottom is required to allow for

sediment build up.

Min. 60

25

5. Electrical Connection

5.1 Electrical installation should be carried

out in accordance with the local

electrical code. Make sure that the

electricity supply has been switched

off before electrical connection.

5.2 Resulting in electrical hazard

warning mark has been marked

outside the connecting box. Be

careful.

~ 2 ~

Fig. 3

5.3 Electrical specifications (voltage, hertz)

are shown on the pump nameplate. Verify

that the power supply voltage and hertz

match pump requirement. An external

ON/OFF switch must be installed.

5.4 Electrical connection should be in

accordance with diagram shown on

connecting box, and motor current should

be within rated amps as shown on

nameplate. Three phase pump requires

extra magnetic starter with protection.

5.5 Three phase motor must check rotating

direction. The rotating direction indicated

on the fan cover, is counterclockwise

viewing from fan cover end. Interchanging

any two leads with power off can reverse

the pump rotation.

5.6 The position of the motor connecting box

is adjustable. Referring to Fig.3, the

adjustment can be done by removing the

motor fan cover, unscrewing the frame

bolts, turning the motor casing and

connecting box subassembly together to

proper position. Finally, screw the frame

bolts tight, and put the fan cover back.

90

0

180

270

o

o

o

o

6. Start-Up

Before start the pump, re-verify the

following items.

6.1 Verify if three phase pump rotation is

correct. The rotating direction should be

counterclockwise viewing from fan cover

end.

6.2 Piping and joints should be fitted carefully

to prevent leak. Leak in the piping will

cause the pump hydraulic lost.

6.3 The pump has been filled with liquid.

6.4 No any foreign objects block the suction

filter.

7. Operation and Maintenance

The pump can not be operated

under the fully closed of discharge

outlet continuously, because it will

raise the liquid temperature

abnormally, and damage the pump

after 5 minutes.

7.1 Lubrication

The mechanical seal and shaft sleeves

inside the pump are lubricated by working

liquid.

7.2 Suction Filter

Suction filter should be always kept clean

to make sure no any foreign objects block

the filter in order to have best

performance.

7.3 Periodic Examination

The following check items should be

carried out periodically to ensure the

normal operation.

7.3.1 Check the discharge and output

pressure of working liquid.

7.3.2 Check the leak of piping and joints.

7.3.3 Examine the motor starter/container.

7.3.4 Test all the pump control function.

7.4 The pump can not be used to transfer

explosive liquids. Extra protective device is

required if the working liquid temperature

exceeds 60

ƨ

to avoid scald hazard.

7.5 The pump should not be used in the

transferring of toxic or contaminated

liquid. Service and maintenance will not

be provided, if the pump application is not

in compliant with the installation and

operation procedures. The user must take

the responsibility for the damage.

8. Sound Pressure Level

MODEL

TPK2T3-3

TPK2T5-5

TPK4T3-3

TPK4T5-5

[ dB(A) ]

<70

<70

<70

<70

<70

TPK4T8-8

~ 3 ~