8

8. Installation

Safety instructions

Warning: Risk of impact from falling fan or fan parts.

•

Before installation, check the surface for load-bearing capacity.

•

Consider all static and dynamic loads when selecting lifting equipment and fasteners.

General safety instructions

•

Installation may only be carried out by appropriately qualified persons, for details, see Table 1 Qualification, page 2.

•

Move the impeller of the fan by hand before installing it to check its freewheeling.

•

Provide contact protection, suction protection and safety distances according to DIN EN ISO13857 and DIN 24167-1.

•

Prevent foreign particles from being sucked in.

•

To prevent vibration transmission to the duct system, we recommend using the flexible connectors from our

accessories, see chapter Accessories.

Requirements

•

Make sure that the fan and all its components are undamaged.

•

Make sure that there is sufficient space for mounting the fan.

•

When mounting the device, protect it from dust and moisture.

•

Make sure that the specifications on the type plate (fan and motor) correspond to the operating conditions.

•

Mount the fans so that there is sufficient access for troubleshooting, maintenance and repair.

9. Installation of the ventilation system

Important

Leaky roof due to incorrect installation

The roof seal (e.g. plastic or bitumen foil) must be pulled under the base plate of the roof fan and fastened there.

Important

Leaky duct system

When installing the roof fan and accessories, all mounting surfaces must be sealed airtight.

Important

Condensate formation due to cold bridges

If the fan and accessories are insufficiently insulated, condensate may form.

1. Check whether the fan and accessories form a cold bridge.

2. Insulate the fan and accessories sufficiently

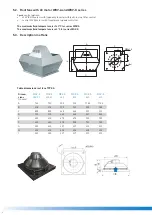

Installation example WDV-K series

Roof plinth must be created

on site