10. Troubleshooting

WARNING!

Before troubleshooting, read and understand the

Service and Maintenance Safety on page 47.

Set the machine to a safe condition.

For engine troubleshooting, see the engine manufacturer's

manual.

The following table lists some of the problems that can occur

and gives possible causes and solutions.

If you find a problem that is difficult to solve, even after reading

this information, please contact your local dealer, the distributor,

or Wallenstein Equipment. When you contact someone, please

have the serial number of your product available. To find the

serial number on your machine, see

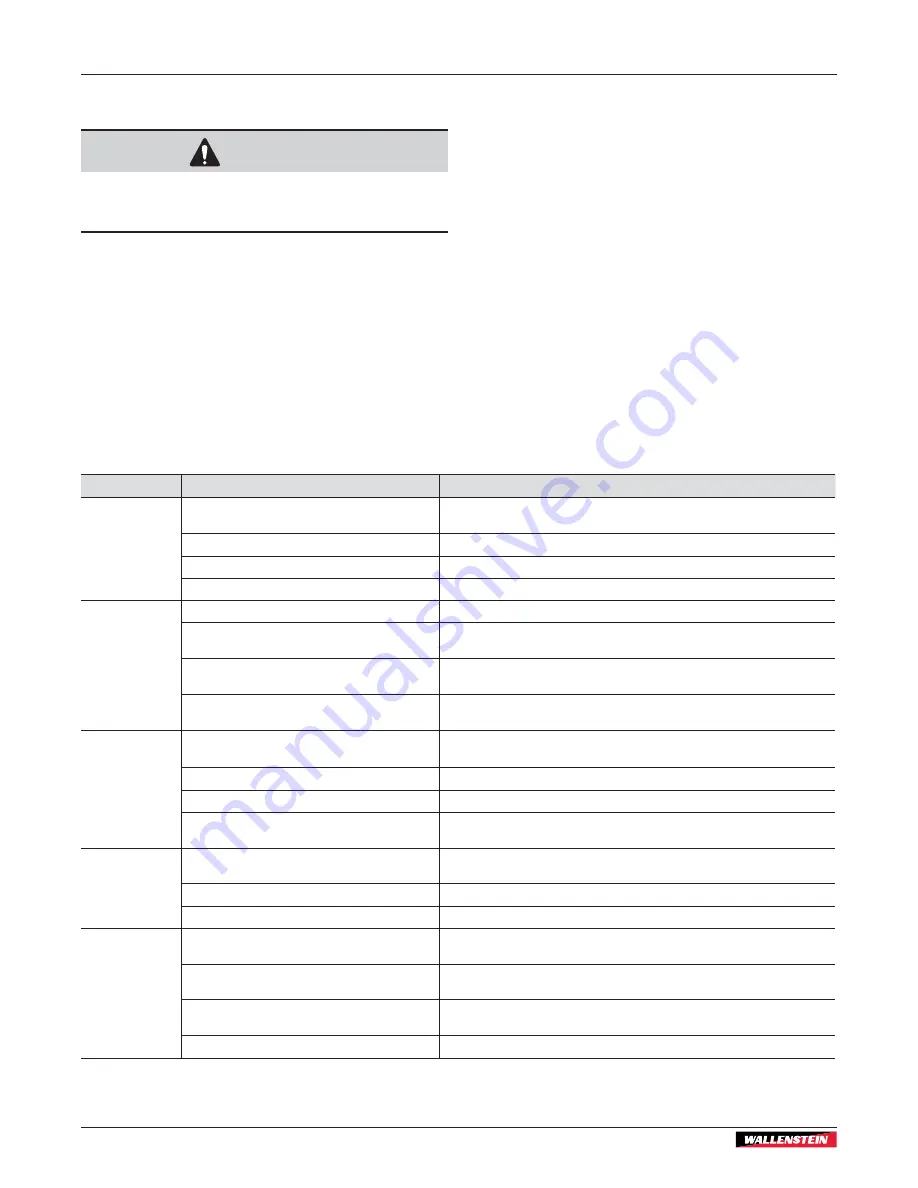

Problem

Possible cause

Solution

The rotor does

not turn.

The discharge chute is obstructed.

Remove all material from the discharge chute. For instructions, see

The rotor is blocked.

Remove the blockage. For instructions, see

The drive belt is loose or broken.

Set the drive belt tension. For instructions, see

The clutch is seized.

Replace the clutch.

Material is

moving into the

machine too

slowly.

The engine or rotor speed is too slow.

Set the engine throttle to

Fast

to increase the rotor RPM. See

The knives are not sharp or the clearance is

incorrect.

Check the rotor and ledger knives. If necessary, rotate, sharpen, or replace

the knives. For instructions, see

The rotor knife angle is incorrect.

Sharpen the rotor knives to the specified 45° angle and check that the

knives are installed correctly. For instructions, see

The discharge chute is blocked.

Remove all material from the discharge chute. For instructions, see

There is unusual

machine

vibration during

operation.

A rotor knife is broken or missing.

Check the rotor knives. If necessary, rotate, sharpen, or replace the knives.

For instructions, see

The rotor could be be bent.

Turn the rotor to see if it wobbles. If the rotor wobbles, replace the rotor.

The rotor bearings failed.

Replace the rotor bearings.

Fasteners are loose.

Use a calibrated torque wrench to torque the fasteners to the correct

specifications. See

The engine does

not start.

The emergency stop button is on.

Reset (turn off) the emergency stop button. Turn the button clockwise and

There is a problem with the engine.

See the engine manufacturer's manual.

The clutch is seized.

Replace the clutch.

The wood chip

quality is poor.

The knives are not sharp.

Check the rotor and ledger knives. If necessary, rotate, sharpen, or replace

the knives. For instructions, see

The drive belt is loose or worn.

Examine the drive belt. If necessary, adjust the tension or replace the drive

belt. For instructions, see

The material being chipped is poor quality.

The material is small or rotting. Mix the material with higher quality

material.

The ledger knife clearance is incorrect.

Set the ledger knife clearance. For instructions, see

Troubleshooting

BXT72S

Wood Chipper

66

Содержание BXT72S

Страница 35: ...02220 Figure 20 Set up the machine BXT72S Wood Chipper Operating Instructions 35...

Страница 41: ...02225 Figure 26 Transport position BXT72S Wood Chipper Transport 41...

Страница 45: ...02227 Figure 30 Storage position BXT72S Wood Chipper Storage 45...

Страница 75: ......

Страница 76: ...WallensteinEquipment com...