Controls

BXM32, BXM42

3-point Hitch Chipper-Shredder

28

WARNING!

Risk of fi ngers being severed or serious injury

to hands in this area! Keep hands and feet out of

inlet and discharge openings while machine is

operating.

W061

The shredder intake chute has a spring-loaded gate to allow the

material in the hopper to flow into the shredder rotor blades. The

gate keeps material from flying out when closed.

There is a gate control lever on both sides of the shredder

intake. Move the lever down to allow the material to move into

the shredding rotor. Release the lever and the spring closes the

gate.

BXM42 has dual gates. BXM32 has a single gate with levers on

each side.

00898

Fig. 23 –

BXM32 Shredder Feed Gate

6.5 Chipper Feed Hopper

WARNING!

Risk of fi ngers being severed or serious injury

to hands in this area! Keep hands and feet out of

inlet and discharge openings while machine is

operating.

W061

WARNING!

Risk of hands or feet being severed or seriously

injured in this area! Never operate the chipper

with the feed hopper raised in the transport

position. Chipper feed hopper must be lowered

and bolted in place for operation (BXM42 only).

W060

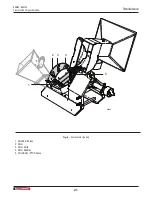

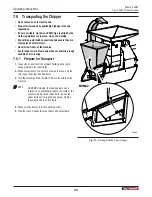

Wood material is slid into the feed hopper past the safety

curtain and into the rotor. The material is drawn in as it engages

the rotor. The safety curtain inside the feed hopper is there to

protect the operator from flying debris. Reaching into the feed

hopper past the curtain when the chipper is operating risks

contacting the rotor blades.

Use a stick or branch to push any piece of material into the rotor

that does not move on its own.

The feed hopper on the BXM42 can be unbolted and raised up

for travel purposes, if the width of the machine is of concern.

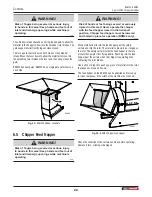

00901

Fig. 24 –

BXM42 Chipper Feed Hopper

Check the condition of the curtain each day before operating.

Replace if torn, missing or damaged.