73

Maintenance Instructions

ADJUSTMENTS

ADJUSTMENTS

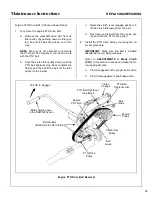

Safety Switches

There are three (3) safety interlock switches on the

tractor. Use the panel nuts on the switch body to po-

sition the switch for proper activation of the switch.

The adjustment procedure for each switch is:

Seat Switch

Adjust switch position in body panel to achieve a

1/32 to 1/16 in. (.79 mm to 1.59 mm) air gap between

the switch plunger and seat frame with no weight on

the seat. Test for proper operation.

FSC Neutral-Park Switch

1.

Place the FSC in NEUTRAL-PARK position.

2. Adjust switch to the point where the starter en-

gages when the ignition switch is turned to the

start position.

3.

Adjust switch position forward an additional 1/2

to 1 turn of the panel nuts.

NOTE: If the switch cannot be adjusted forward

enough to achieve proper function, it may be

necessary to bend the switch mounting bracket

slightly.

PTO Switch

With the PTO engaged, adjust switch to achieve a

1/64 to 1/32 in. (.40 mm to .79 mm) gap (plunger ex-

tension) between the switch body and the actuator

plate.

Tail Wheel Bearing Preload

Preload the tail wheel bearings by tightening the ax-

le nut until the wheel begins to tighten as it turns (not

spin freely), then loosen the nut 1/2 to 1 turn. The

wheel should spin freely without excessive end play.

Lock the axle nut with the set screw in the nut.

DANGER

If the engine must be running to perform

a maintenance adjustment, keep hands,

feet, and clothing from moving parts. DO

NOT wear jewelry or loose clothing.

Содержание MT 20.0 HP

Страница 53: ...Maintenance Instructions LUBRICATION 49 Chassis and Deck Lubrication Points...

Страница 87: ...83 Maintenance Instructions ELECTRICAL SYSTEM Wiring Diagram Model MT...

Страница 88: ...84 Operator s Notes...

Страница 89: ...85 Operator s Notes...

Страница 90: ...86 Operator s Notes...