Содержание MT 20.0 HP

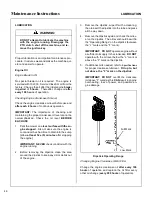

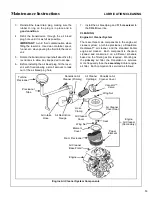

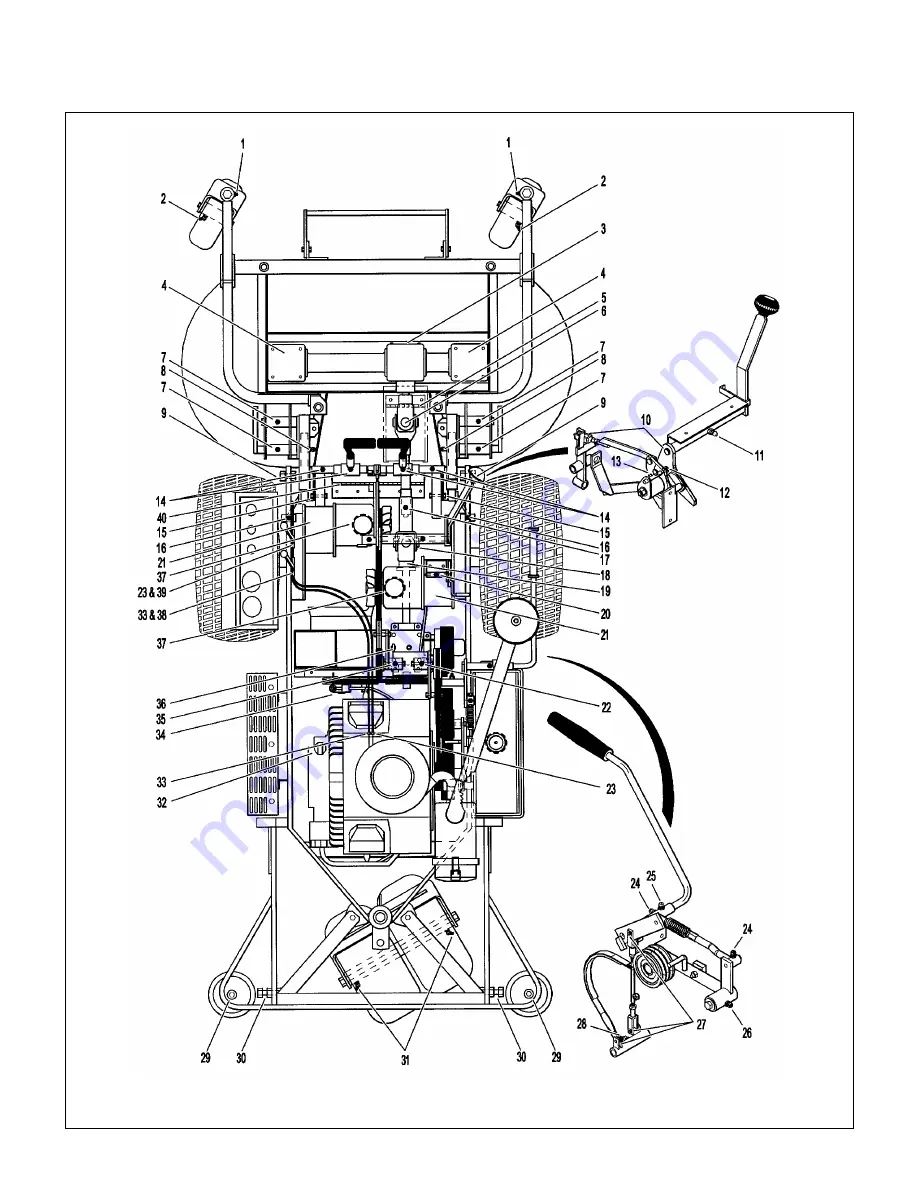

Страница 53: ...Maintenance Instructions LUBRICATION 49 Chassis and Deck Lubrication Points...

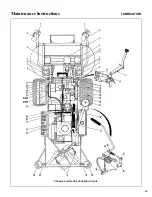

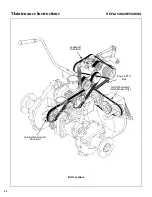

Страница 87: ...83 Maintenance Instructions ELECTRICAL SYSTEM Wiring Diagram Model MT...

Страница 88: ...84 Operator s Notes...

Страница 89: ...85 Operator s Notes...

Страница 90: ...86 Operator s Notes...