Maintenance Instructions

B23

Checking and Servicing

58

Spark Plugs

Every 200 hours

of operation, remove the spark

plugs, inspect, clean, and reset the gap (or replace

with

new plugs

). Before removing the spark

plugs, clean the area around the base of the plugs

to keep dirt and debris out of the engine. Clean

spark plugs with a wire brush. DO NOT use an

abrasive grit type cleaner. If the electrodes are

burned short or pitted, replace plugs with Cham-

pion

®

type RC12YC (or equivalent). Check spark

plug gap with a wire-type feeler gauge and set the

gap at 0.030 in. (0.76 mm). Reinstall and tighten

to between 18 and 22 lb·ft (24 to 30 N·m).

Ignition Wires

Good preventive maintenance calls for complete

replacement

of spark plug wires

every two (2)

years.

Fuel Lines and Clamps

Every year,

inspect the fuel supply line from the

tank to engine for deterioration or damage. Also,

inspect the fuel line

clamps for tightness

. Good

preventive maintenance calls for complete

replacement

of fuel lines and clamps

every two

(2) years.

Blade Brake Action

WARNING

It is important to check and maintain blade

brake action for safe operation of the ma-

chine.

Check the function of the cutter blade brake by

engaging the blade clutch (PTO), operating the

engine at full throttle, then disengaging the clutch

and measuring how quickly the blades stop.

Watch the rotation of the blade drive shaft as a

visual indication that movement has stopped. If

the brake is

working properly, all rotation will

stop five (5) seconds after disengagement

of

the clutch. If the brake system malfunctions—

blades do not stop in five (5) seconds, the electric

clutch/brake assembly will need to be repaired or

replaced. Contact your Walker Dealer for this

service.

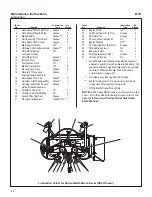

PTO U-Joints

The PTO U-joints should be inspected

yearly

for

looseness and wear. If either is noticed, the

respective shaft or tube should be replaced. A

worn U-joint can cause vibration and extensive

damage to the PTO and the whole machine.

Engine Starter

Yearly or every 500 hours

disassemble and clean

the solenoid shift starter. Refer to the Kohler Ser-

vice Manual for this procedure or contact an autho-

rized Kohler engine dealer to perform this service.

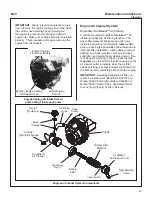

Safety Switch System

WARNING

It is important to check and maintain the

safety switch system for safe operation of

the machine.

There are four (4) safety interlock switches on the

tractor; Seat Switch, FSC Neutral-Park Switch,

PTO Switch, and Parking Brake Switch.

NOTE:

There is a 1/2 second time delay function

on the seat switch to avoid engine power interrup-

tion when driving over bumps.

If any of the following conditions occur during

starting or operating, a safety interlock switch may

be malfunctioning. Contact your Walker dealer for

troubleshooting and/or replacement.

● With or without an operator in the seat, the

engine starts

with the Forward Speed Control

(FSC) and/or the PTO engaged, or the parking

brake disengaged.

● With an operator in the seat and the parking

brake engaged, the

engine starts but dies

soon after the parking brake is disengaged and

the Forward Speed Control (FSC) or PTO is

engaged.

●

Without

an operator in the seat, the engine

starts and

continues to run

with the Forward

Speed Control (FSC) and/or PTO engaged, or

the parking brake disengaged.

● With an operator in the seat, the Forward

Speed Control (FSC) and PTO disengaged,

and the parking brake engaged, but the

starter

will not engage.