Instruction & Technical Manual | 17

8.1.6 Programming dryer

Once it has been decided to change the default settings, and communications have

been established and the dryer existing valves read the procedure for change is:

• Click into the box you wish to change.

• Over write with the items you require (note stage times are in 10 second intervals).

• Click “Program dryer” ( a warning will appear asking to confirm the change).

• Click to confirm and this will change operating parameter.

• Click in real time to check set up.

2.

Read dryer

Reads the current settings of the controller

3.

Program dryer

Programs the controller with the new settings

4.

Real Time view

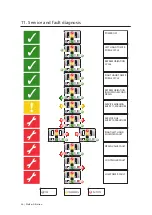

This screen can be opened by clicking the real time screen. In addition to the main

display panel shown previously there is also a real time view, which illustrates the

operation of the dryer valves as it happens. It also counts down the remaining time to

run on the valve operation. This is useful in confirming faults, which are displayed with

the LED’s on the front display panel.

To view the status of the controller in real time, click the ‘real time’ view switch. A new

window will appear animating the dryer controller status in real time.

The following information is shown:

• The stage the controller is in through its cycle, including remaining time on the

particular stage.

• Valve conditions

• Power condition

• Cartridge and valve service conditions

• Energy management condition

• Alarm condition

5.

Load settings

Allow previously stored settings to be loaded into the controller

6.

Stage times

• Tower 1 & Tower 2 – Indicates the time that a tower is depressurised.

• Re-pressurization – Indicates the re-pressurization time set on the controller.

• Link – Enables or disables the tower 1 & tower 2 settings to be linked.